The KMC Difference: Partnership in Every Part

Real engineering partnerships start with understanding — not assumptions.

At KMC, we don’t just make parts; we help our OEM partners make better ones. Every solution begins with listening, learning, and engineering together. Because when collaboration is built into every step, precision, performance, and trust become the outcome.

Why Do Major OEMs Trust KMC?

We turn complex challenges into precision solutions, aligning your vision with our engineering expertise. By engaging early, we help you optimize designs, reduce cost, and bring your best ideas to life with confidence.

Team of Experts

Our engineers, designers, and quality specialists turn complex ideas into manufacturable solutions that perform.

True Partnership

We work alongside you—solving challenges, building trust, and delivering results through open collaboration.

Concept to Production

From design to production, we bring the insight and precision to make every part a reality.

Let’s Build Something Better Together.

KMC Difference

Team of Experts

- Business Development: Strategic growth partner fueled by customer relationships, tailored solutions, and long-lifecycle partnerships.

- Sales Engineering: Experienced, hands-on technical support providing solutions for application needs before, during and after product launch.

- Cross Functional: Expertise in delivering accurate, timely cost estimates aligned with Production capabilities and market costs.

- Quality: Providing guidance through process-specific capability knowledge to ensure customer success, seamless part launch and ongoing program success.

- Supply Chain Management: Driving alignment between demand and supply through data-driven forecasting, collaborative planning, and optimized resource allocation.

KMC Difference

True Partnership

- Trust: Built through transparency, responsiveness, and reliability across every stage of the relationship.

- Accessibility: Direct access to experts who listen, respond, and act — no layers, no delays.

- Collaboration: We work alongside you to solve problems, adapt quickly, and share in the success of every breakthrough.

- Shared Success: Partnership means aligning our efforts with your outcomes — turning goals into measurable results.

KMC Difference

Concept to Production

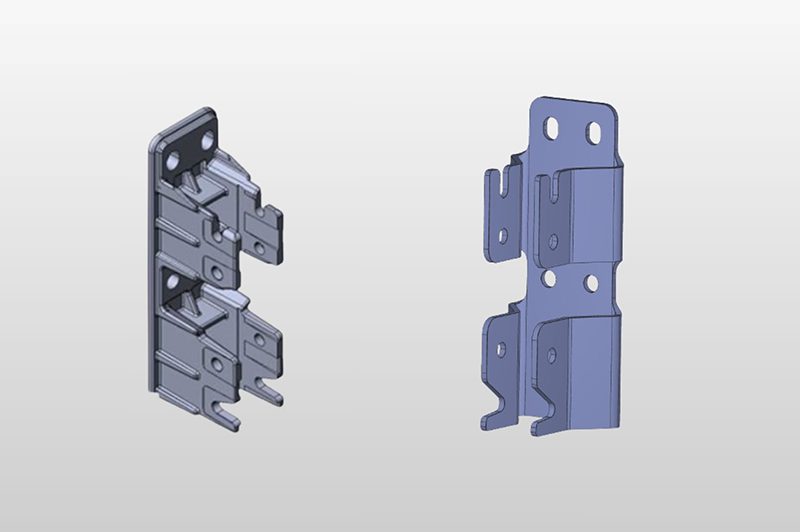

- Discovery: Every project begins with a deep review — part prints, models, and context — to fully understand the scope and application needs.

- Collaboration: Cross-functional teams (Cost Estimating, Quality, Business Development, Sales Engineering, Tool Engineering) work together to explore solutions and identify challenges early.

- Partnered Design Reviews: Customer/Supplier collaboration review sessions are held to ensure feasibility alignment prior to product launch.

- Precision Planning: Solutions, concerns, and exceptions are mapped, costed, and refined — ensuring a clear path from quote to build where our formal APQP process is followed.

- Delivery: Final solutions are presented with confidence — engineered for manufacturability, performance, and long-term value.

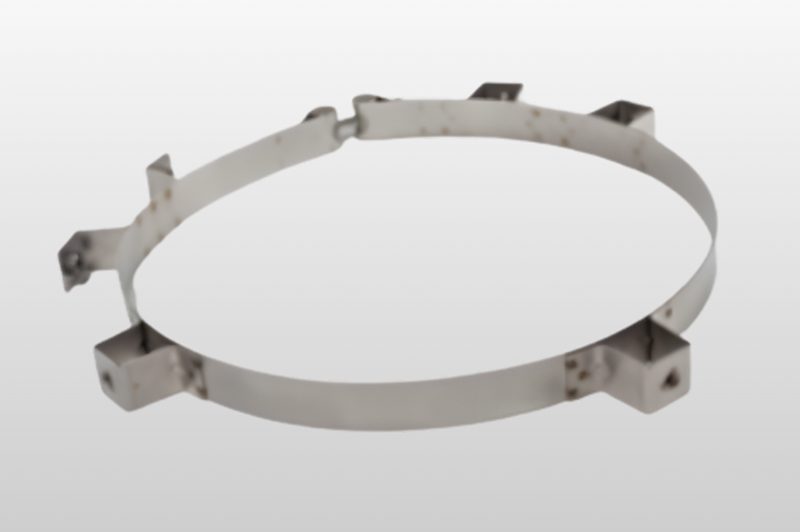

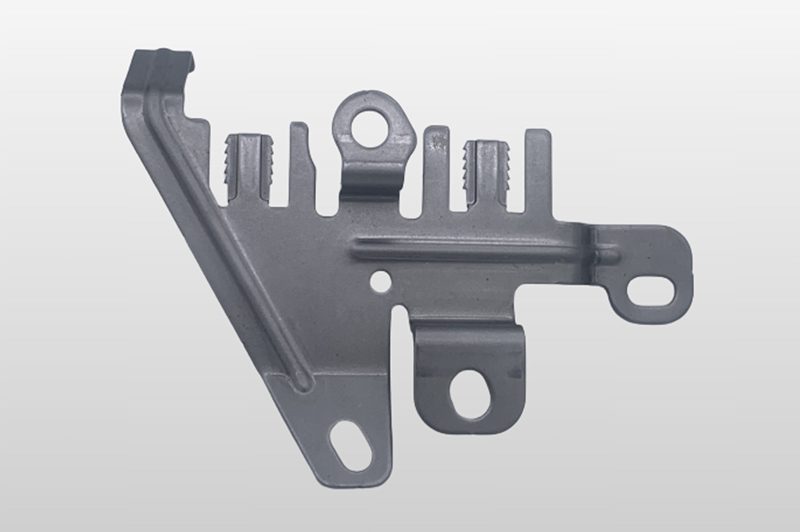

Our Case Studies

Collaborative Engineering. Proven Results.

Every success story starts with collaboration. See how KMC helps OEMs solve design challenges and turn complex ideas into precision-engineered results.

What Our Customers Have to Say…

“KMC is a very reliable supplier that lives up to their commitments on on-time delivery and quality. They make my job easier because I don’t have to chase updates or fix issues—they simply deliver.”

“KMC’s engineers don’t just tell us what can’t be done — they show us how it can be done. Every design challenge is met with a smart, practical solution.”

“When other suppliers fell off or stopped responding, KMC stayed engaged. Their determination and communication made all the difference — they kept the project moving when others gave up.”

“KMC didn’t just ship parts — they owned the outside processes and quality checks, coordinated vendors, and brought solutions to the table.”

“One of KMC’s biggest advantages is their in-house tooling division. They have full control over tooling design, cost, and lead time, which keeps projects on schedule and ensures parts are made right the first time.”

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

Get in Touch

It’s Easy to Get Started

Ready to collaborate? Schedule a meeting with our engineering team to explore how KMC can accelerate your next program.