KMC Unveils New Brand and Website Reflecting Its Engineering-Led Approach to OEM Manufacturing

Kickhaefer Manufacturing Company (KMC), a leading U.S. manufacturer of precision metal components and assemblies, has launched a new brand identity and website that reflect the company’s evolution into a collaborative, engineering-driven partner for OEMs.

The new site website introduces KMC’s modernized brand, refined messaging, and expanded content focused on what sets the company apart — collaborative engineering, certified quality, and proven performance across every stage of manufacturing.

“Our goal was to create a brand and digital experience that reflect who KMC is today — a hands-on engineering partner that helps OEMs design and manufacture smarter,” said Gerry Schwarz, President and CEO of KMC. “This new site tells that story clearly and positions us for the next phase of growth.”

Built for Engineers and OEM Buyers

Designed in partnership with the Measured in Millions (MiM) team at the Vx Group, the new website serves as a practical resource for engineers, design teams, and procurement professionals seeking reliable, collaborative manufacturing support.

Rather than focusing solely on production capabilities, the site emphasizes how KMC works with customers — partnering early in the design cycle to improve manufacturability, reduce cost, and shorten lead times.

Key pages highlight KMC’s full range of services, including:

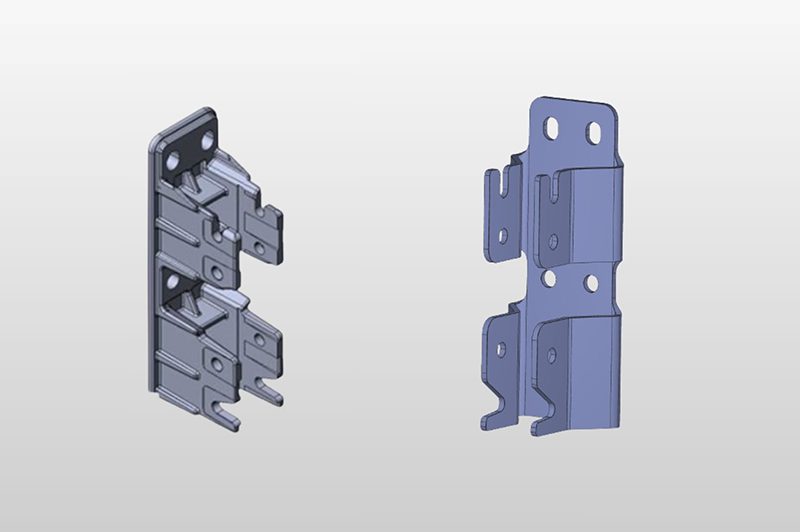

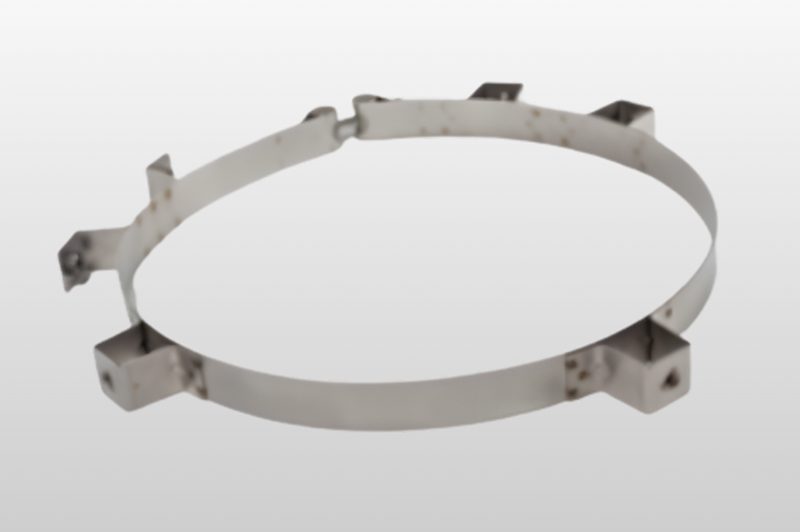

- Precision Metal Stamping

- Laser Cutting & Fabrication

- Welding & Complex Assemblies

- Tool & Die Engineering

- Prototyping & Engineering Support

- Value-Added Services

Each capability section outlines how collaboration adds measurable value, showcasing the company’s depth of experience and technical expertise.

“Engineers and buyers don’t just want a quote — they want a partner who understands design intent and manufacturability,” said Matt Stefanski, Director of Business Development. “This new site makes it easier for them to see how KMC adds value from concept to production.”

A Brand Built on Collaboration

KMC’s rebrand centers around its long-held belief that the best manufacturing outcomes come from collaboration. The refreshed messaging and visuals bring this philosophy to life — emphasizing relationships, problem-solving, and precision over simple production.

This direction builds on the company’s proven foundation:

- Over 100 years of manufacturing expertise

- A 250,000+ square-foot footprint across multiple Wisconsin facilities

- Approximately 300 employees supporting OEMs in agriculture, heavy equipment, transportation, specialty vehicle, and data center markets

- Certified ISO and IATF quality systems

- Full in-house tool and die engineering, prototyping, and complex assembly capabilities

“This rebrand puts focus where it belongs — on our customers and the value we create together,” said Craig Goettl, Director of Sales Engineering. “It captures what has made KMC successful for decades: collaboration, expertise, and quality.”

Let’s Build Something Better Together.

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

What Our Customers Have to Say…

“KMC is a very reliable supplier that lives up to their commitments on on-time delivery and quality. They make my job easier because I don’t have to chase updates or fix issues—they simply deliver.”

“KMC’s engineers don’t just tell us what can’t be done — they show us how it can be done. Every design challenge is met with a smart, practical solution.”

“When other suppliers fell off or stopped responding, KMC stayed engaged. Their determination and communication made all the difference — they kept the project moving when others gave up.”

“KMC didn’t just ship parts — they owned the outside processes and quality checks, coordinated vendors, and brought solutions to the table.”

“One of KMC’s biggest advantages is their in-house tooling division. They have full control over tooling design, cost, and lead time, which keeps projects on schedule and ensures parts are made right the first time.”