Design for Manufacturability: How Early Collaboration Creates Better Results

At KMC, collaboration begins long before production starts. For more than a century, the Port Washington–based manufacturer has partnered with OEM engineers to design smarter, more manufacturable components. With in-house tool and die expertise, advanced stamping and fabrication capabilities, and a hands-on engineering team, KMC helps reduce cost and complexity while improving product performance .

Why Early Design Collaboration Matters

Most cost and performance decisions are made during the design stage. KMC’s engineering-led approach ensures manufacturability is considered early—reducing the risk of redesigns, material waste, and production delays .

KMC’s Education & Capability events, for instance, are designed to “teach more, pitch less,” helping engineers understand how subtle design adjustments—like tolerance changes or material selections—can significantly impact manufacturability .

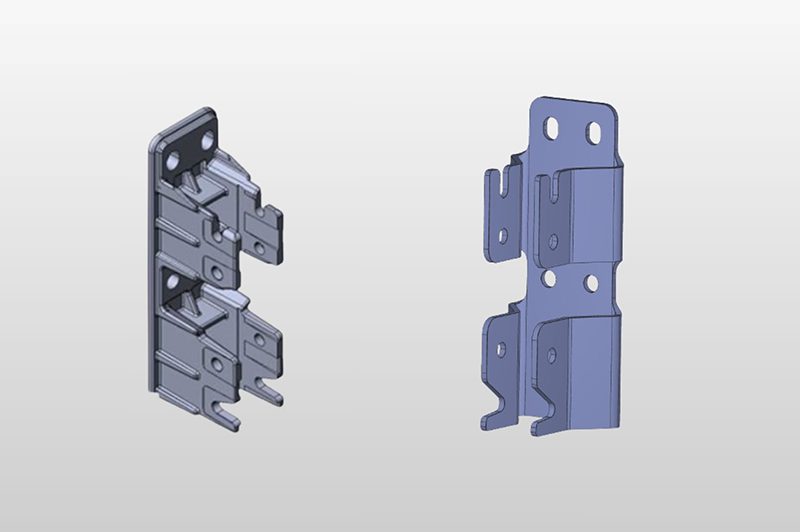

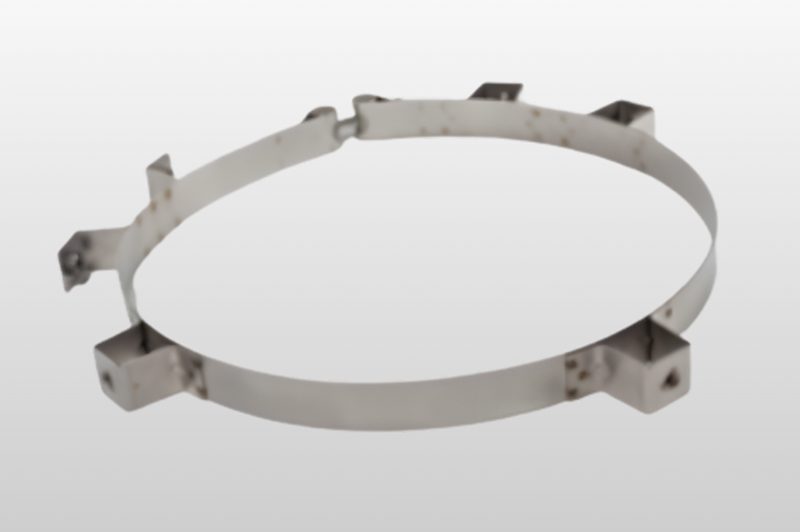

In-House Engineering and Tooling Expertise

KMC maintains its own tool and die shop, allowing engineers to design and maintain tooling for precise, repeatable results across large production runs. This vertical integration supports faster development, better cost control, and long-term quality consistency .

Collaborative Engineering in Action

KMC’s engineering and sales teams work directly with OEM engineers to solve challenges early in the design cycle. This “concept-to-production” mindset allows both teams to evaluate manufacturability together, resulting in designs that are not only functional but optimized for production .

Continuous Improvement Through Education

Beyond daily collaboration, KMC invests in educational events and workshops that help OEM teams design smarter components. These sessions build trust and demonstrate technical expertise while equipping engineers with practical, real-world tools for better decision-making .

The Outcome: Quality, Consistency, and Cost Control

Through early collaboration and integrated manufacturing capabilities, KMC consistently helps OEMs achieve better part quality and program stability—while reducing the total cost of ownership.

Let’s Build Something Better Together.

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

What Our Customers Have to Say…

“KMC is a very reliable supplier that lives up to their commitments on on-time delivery and quality. They make my job easier because I don’t have to chase updates or fix issues—they simply deliver.”

“KMC’s engineers don’t just tell us what can’t be done — they show us how it can be done. Every design challenge is met with a smart, practical solution.”

“When other suppliers fell off or stopped responding, KMC stayed engaged. Their determination and communication made all the difference — they kept the project moving when others gave up.”

“KMC didn’t just ship parts — they owned the outside processes and quality checks, coordinated vendors, and brought solutions to the table.”

“One of KMC’s biggest advantages is their in-house tooling division. They have full control over tooling design, cost, and lead time, which keeps projects on schedule and ensures parts are made right the first time.”