Collaborative Engineering for a Lightweight, Error-Proof Hose Retainer

Introduction

KMC collaborated with an automotive manufacturer on the Ford Super Duty Truck (P708) program to develop a hose retainer for a cooling system. The goal was to create a lightweight, durable, and easy-to-install solution that integrated seamlessly into the existing platform—addressing a known issue with hose support that had led to performance and reliability concerns.

Challenges

Without proper support, the cooling hose was prone to sagging, kinking, or stressing adjacent components—resulting in costly failures. The available mounting location was difficult to access and prone to incorrect installation. As development progressed, additional requirements emerged, including the need for an anti-rotation feature, error-proofing, and a pre-installed fastener to reduce assembly time and complexity.

Solution

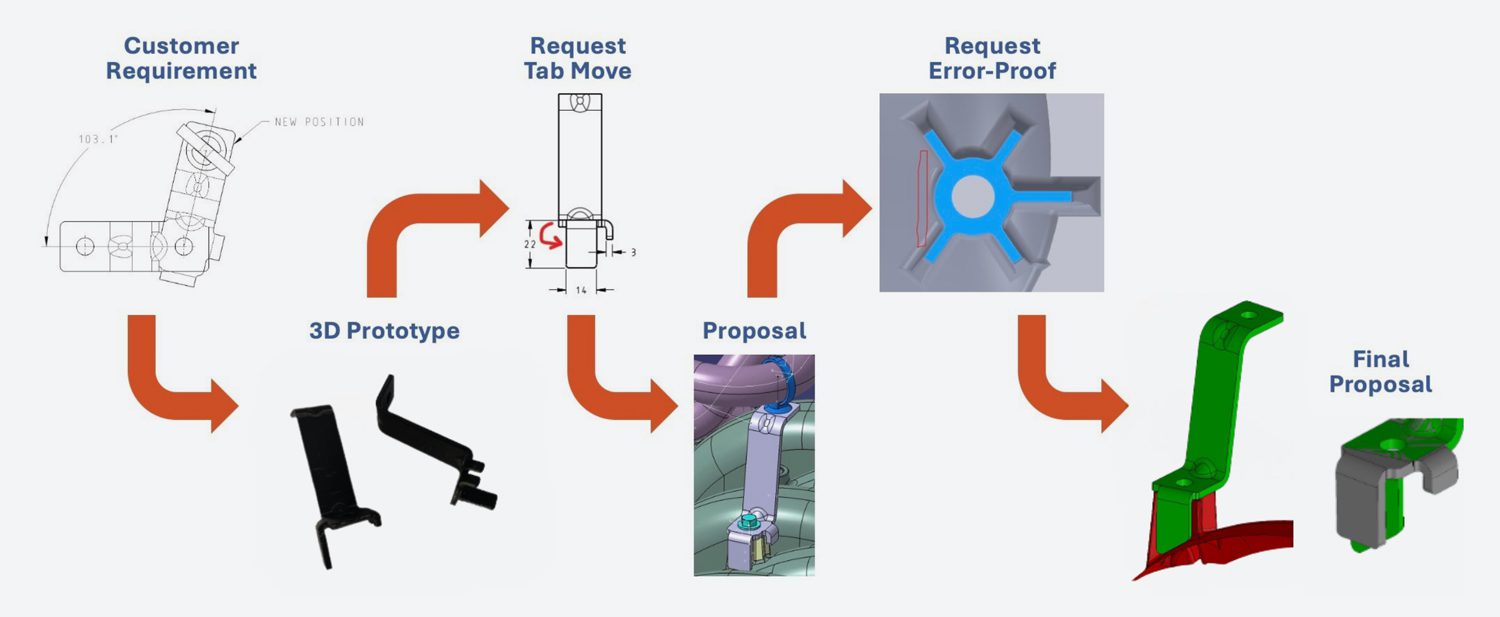

KMC led a full-cycle design and development effort to deliver a custom solution:

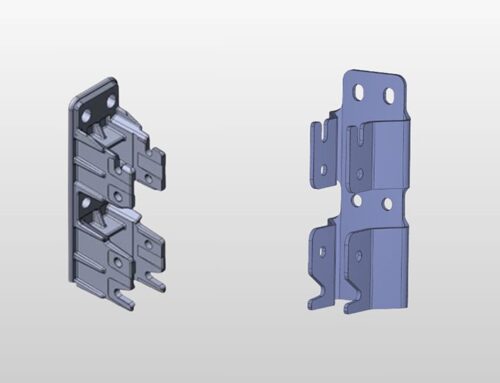

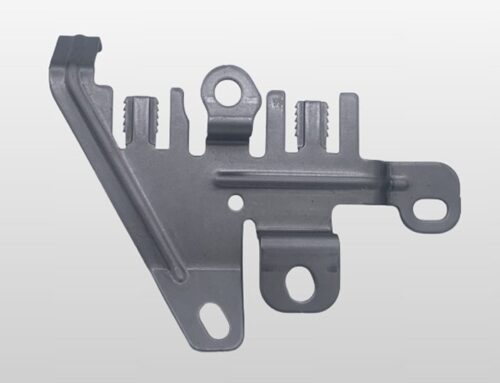

- Designed a robust bracket using 5052-H32 aluminum, offering strength, corrosion resistance, and minimal weight

- Engineered physical features directly into the part to satisfy anti-rotation, error-proofing, and fastener retention requirements

- Delivered CAD models, prints, and 3D-printed prototypes during the collaborative process

- Took advantage of an existing threaded hole in the engine casting to eliminate the need for added modifications

Conclusion

KMC’s collaborative engineering approach delivered a high-performance hose support bracket that:

- Prevented hose and engine failures

- Reduced weight and complexity

- Streamlined installation with anti-rotation and error-proofing features

- Used existing hardware and minimized assembly labor

This solution saved tens of thousands of dollars in potential failure costs and met all of the manufacturer’s targets—low cost, light weight, easy to install, and production-ready.