Collaborating for a Robust Filtration Component Manufacturing Solution

Introduction

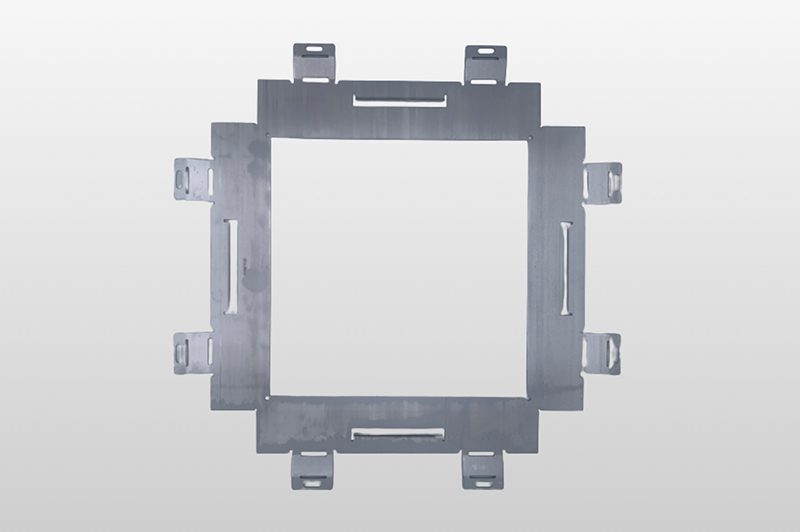

KMC collaborated with heavy equipment manufacturer to resolve a critical issue in the manufacturing of a filtration system component. The existing part design led to severe fit-up issues, causing unacceptable leakage and operational failures. The collaboration required a reengineering effort to restore performance and product reliability.

Challenges

The customer identified serious issues with a component used in their filtration systems. The part, although designed to optimize material usage did not meet print specifications, compromised structural integrity and assembly compatibility. The misalignment led to leaks during customer assembly, high scrap rates, excessive rework and high return volume.

Solution

KMC’s solution involved a shift in the manufacturing approach:

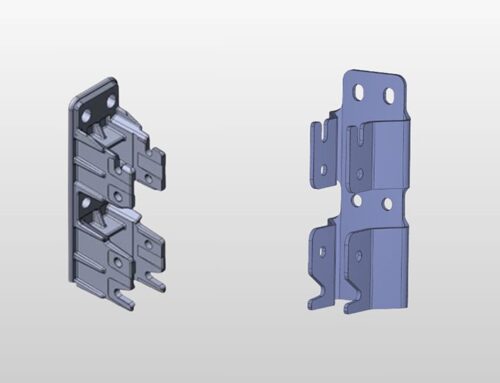

- Material Utilization: Transitioned from a long strip layout to a flat blank that is then folded in

- Process Optimization: Increased the number of bends and decreased the number of welds, which reduced potential leak paths

- Robust Engineering: Though material usage increased, the structural integrity and functionality of the part were significantly improved

- Installation Efficiency: Addressed design challenges that caused interference for final assembly.

Key aspects of the solution included:

- KMC maintained clear and continuous communication with the customer, who provided guidance on design flexibility

- Multiple samples and on-site discussions at the customer’s location facilitated a mutual agreement on a final design

Conclusion

To meet the customer’s growing demand, KMC leveraged its manufacturing expertise to adapt and scale key processes—including punch press, robotic welding, and robotic forming. The customer’s new part design, which addressed longstanding issues dating back to 2018, has proven highly effective:

- Dramatic reduction in scrap and rework

- Stabilized manufacturing processes

- Increased production output in response to rising demand

- 10x increase in volume beginning in late 2023, driven by use in power generation for data centers

- There was no change in part cost for KMC’s optimized design, as the added material and forming time were offset by a faster welding rate.