Welding & Assembly Expertise You Can Trust

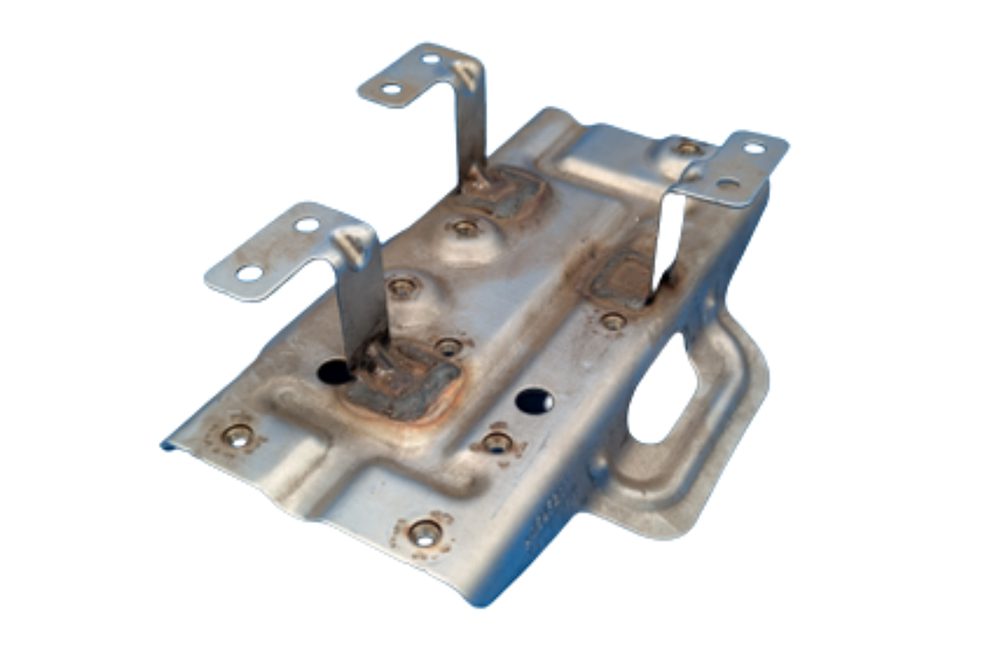

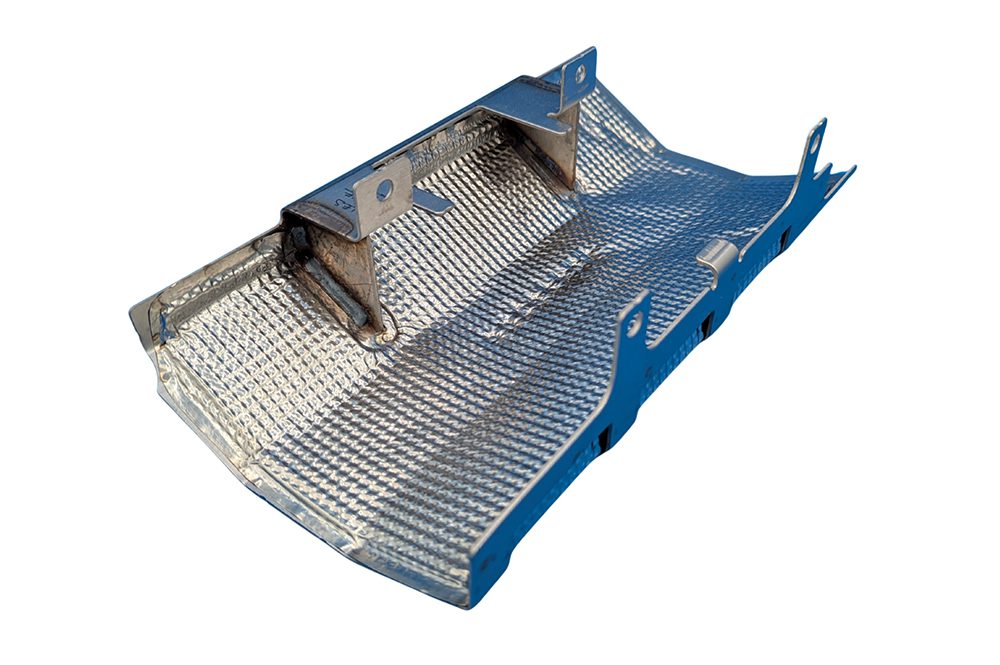

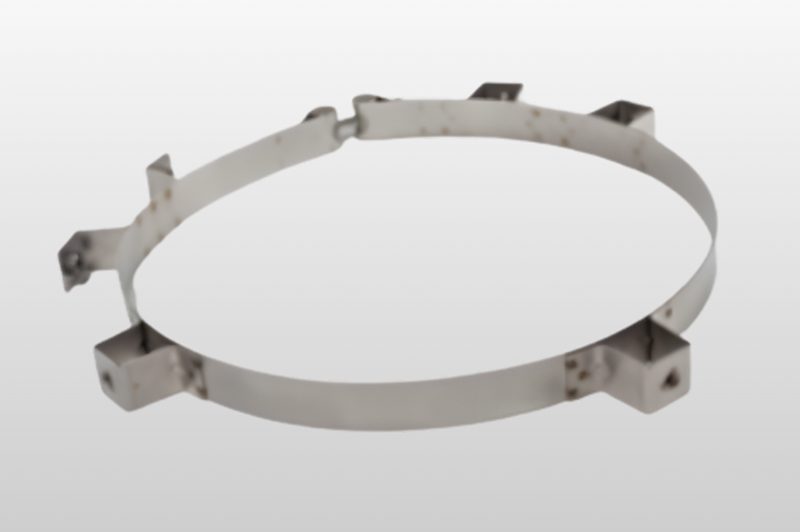

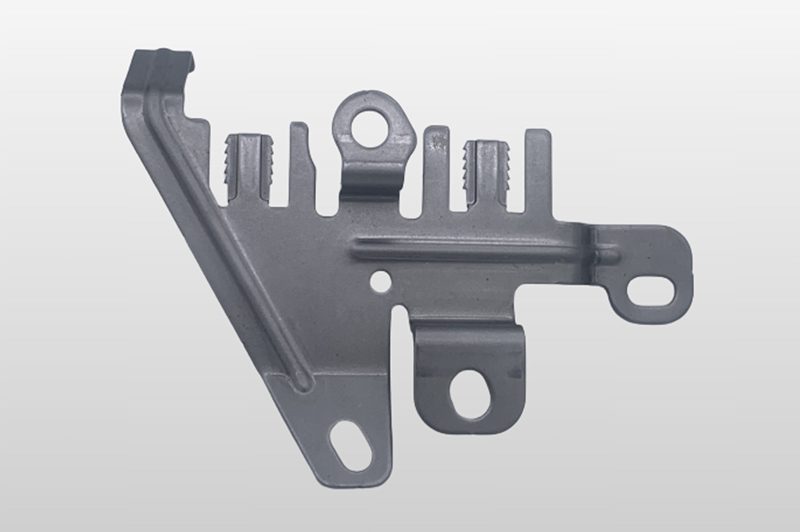

Precision welding and assembly for OEM parts requiring strength, consistency, and quality control.

KMC integrates robotic welding, manual craftsmanship, and engineering insight to create complex assemblies that meet the highest OEM performance and compliance standards.

How We Do It Differently

Our weld and assembly capabilities combine technical precision with close engineering collaboration—ensuring every component fits, functions, and performs as designed.

Certified Welding Expertise

Experienced technicians and robotic systems deliver precision welds meeting ISO and IATF quality requirements.

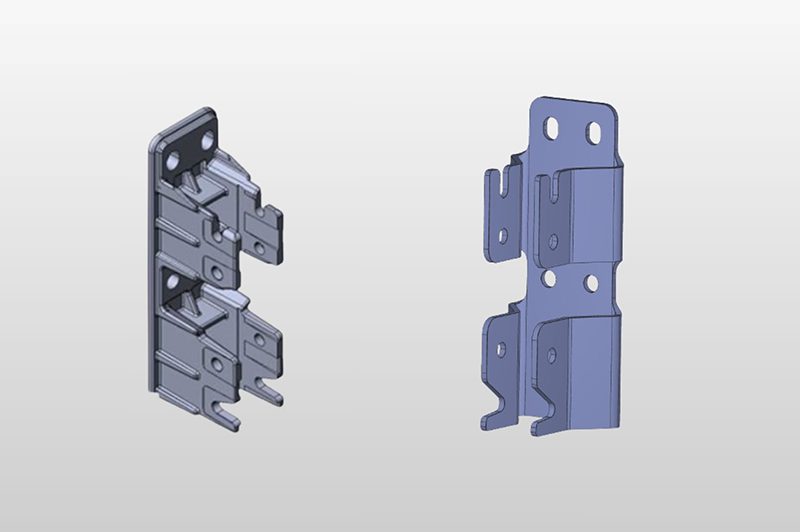

Integrated Engineering Support

Collaborative design reviews identify cost-saving opportunities and ensure assembly feasibility from the start.

Complex, Multi-Process Builds

From welded sub-assemblies to complete structures, KMC manages all fabrication, fit-up, and quality verification in-house.

Let’s Build Something Better Together.

Welding & Complex Assembly

Our Core Welding & Assembly Processes

KMC’s welding and assembly operations center on two core processes—Robotic Welding and Manual Welding—delivering the strength, consistency, and precision required for complex OEM components.

Robotic Welding

EQUIPMENT:

- Four Miller PerformArc Workcenters

- Two-Sided Turntables

- Six-Axis Trunnion and Robot

MATERIAL:

- Carbon Steel

- Stainless Steel

- Aluminum

PROCESSES:

- MIG

- Laser

Manual Welding

EQUIPMENT:

- Conventional Resistance

- C-Frame Resistance

- Rocker Arm Spot Weld

- MIG

- Laser

MATERIAL:

- Carbon Steel

- Stainless Steel

- Aluminum

PROCESSES:

- Projection (weld nut, weld studs, etc.)

- Spot Welding

- MIG

- Laser

Our Case Studies

Collaborative Engineering. Proven Results.

Every success story starts with collaboration. See how KMC helps OEMs solve design challenges and turn complex ideas into precision-engineered results.

What Our Customers Have to Say…

“When other suppliers fell off or stopped responding, KMC stayed engaged. Their determination and communication made all the difference — they kept the project moving when others gave up.”

“KMC didn’t just ship parts — they owned the outside processes and quality checks, coordinated vendors, and brought solutions to the table.”

“We rely on KMC for a high-volume part (~150,000 pieces/month). They ramped without stumbling and quality has been excellent.”

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

Get in Touch

It’s Easy to Get Started

Ready to collaborate? Schedule a meeting with our engineering team to explore how KMC can accelerate your next program.