Integrated Services That Add Real Value

Beyond fabrication, KMC delivers complete OEM solutions with finishing, sub-assembly, and logistics support that reduce complexity and cost.

Our value-added services streamline your supply chain—combining manufacturing, finishing, and packaging expertise to deliver ready-to-install components on time.

How We Do It Differently

KMC brings together engineering expertise, advanced manufacturing, and seamless downstream operations to deliver production-ready components that simplify OEM supply chains and improve performance.

Integrated Assembly Solutions

Custom assembly, kitting, and precision integration ensure every component arrives production-ready and built to your exact specifications.

Finishing & Coating Excellence

Advanced in-house coating, deburring, and surface finishing deliver consistent quality, durability, and appearance across every part.

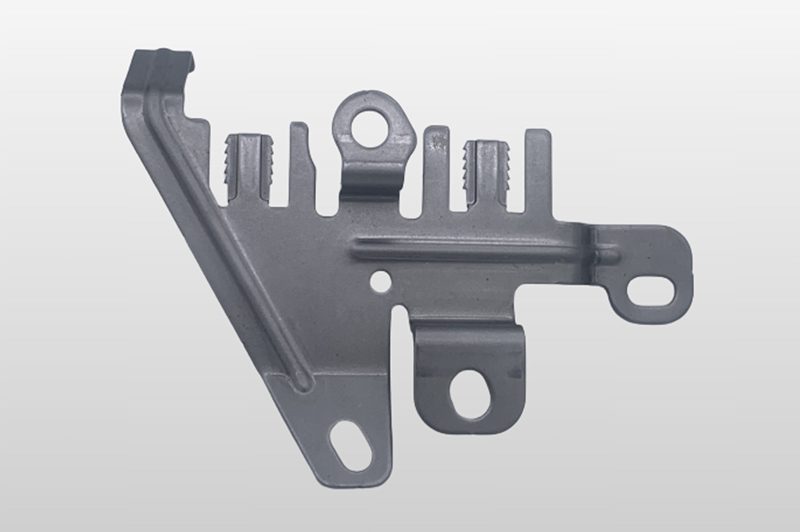

Fabrication & Material Expertise

Engineering-driven material selection and fabrication support optimize manufacturability, reduce cost, and improve long-term performance.

Let’s Build Something Better Together.

Value-Added Services

Our Value-Added Solutions

KMC’s value-added solutions integrates design, fabrication, and finishing—delivering complete, production-ready solutions that simplify OEM supply chains and enhance performance across every component.

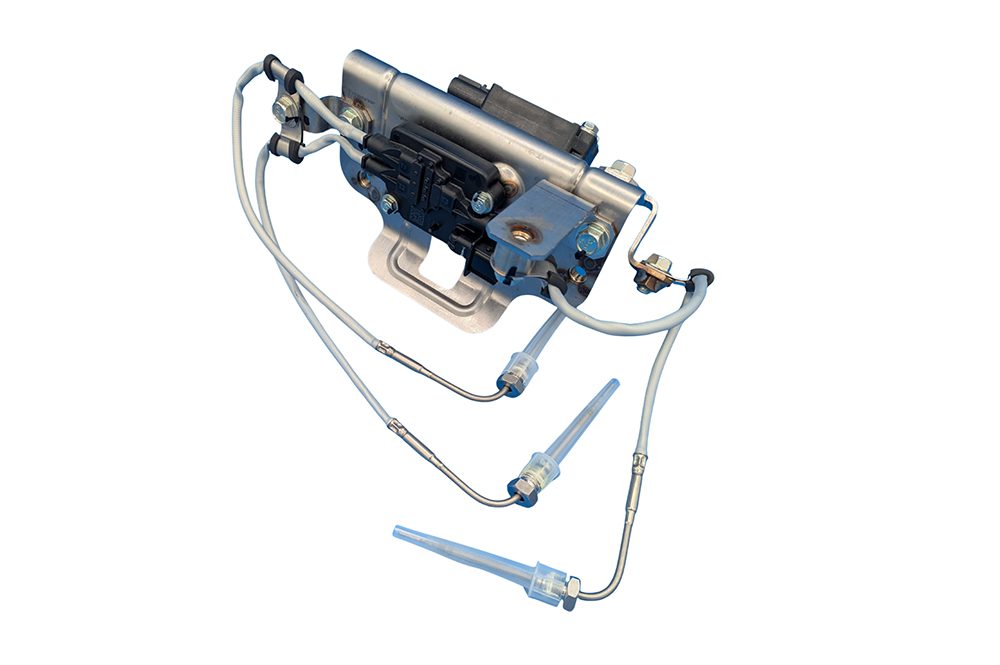

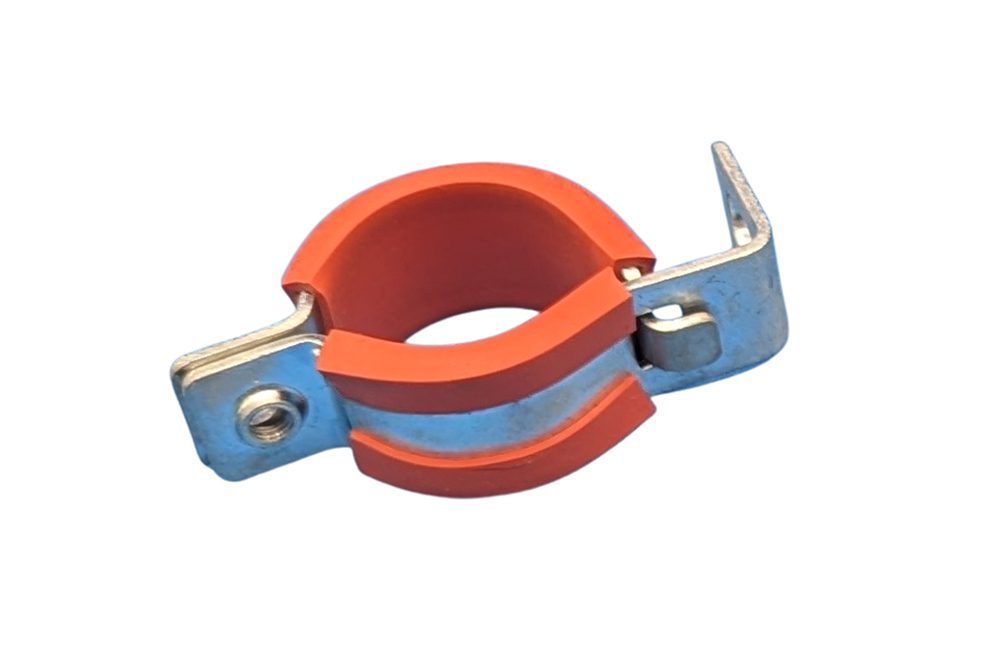

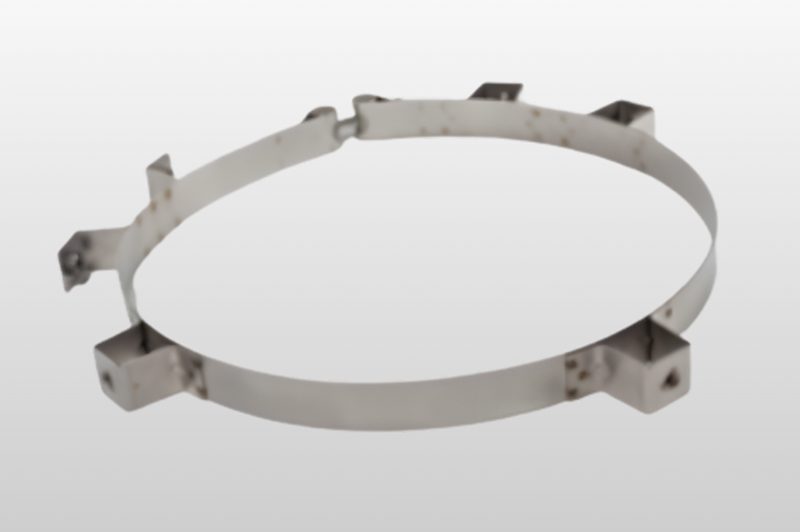

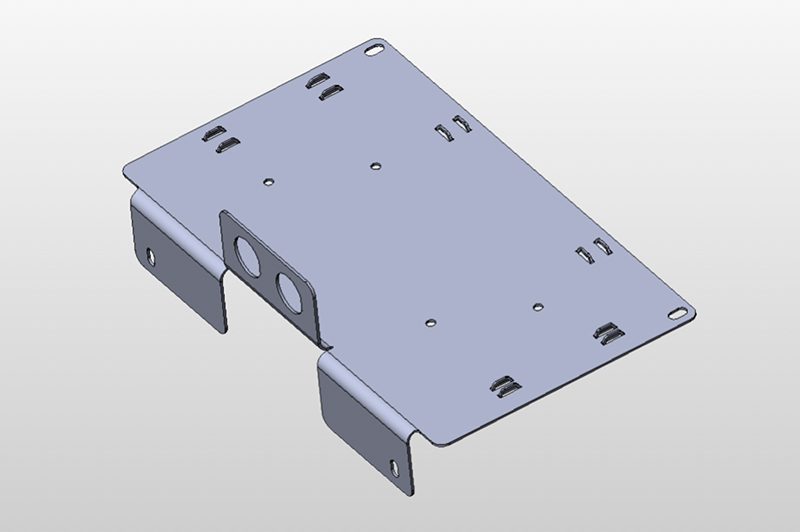

Assembly

EQUIPMENT:

- Custom Assembly

- Manual Assembly Stations

MATERIAL:

- Stamped Components

- Fabrications

- Hardware

- Customer-Specified

- High Temp Silicone

- EPDM

PROCESSES:

- Rivet, PEM & Riv-Nut (AVK)

- Assembly

- Kitting

- Special Pack

- Extrusion Liner Assembly

- Laser Etching

- Labeling

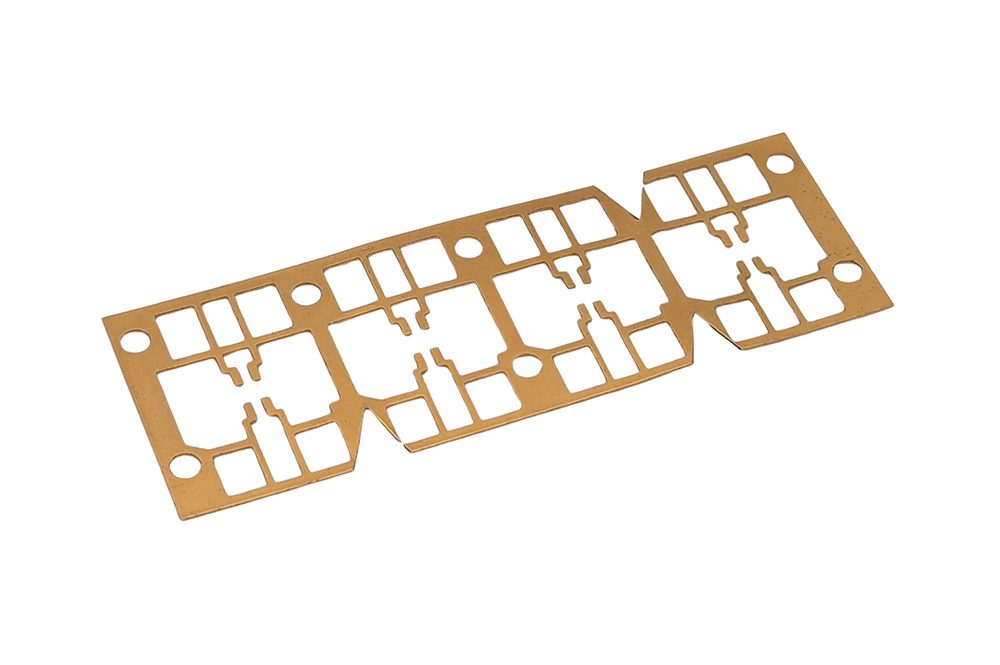

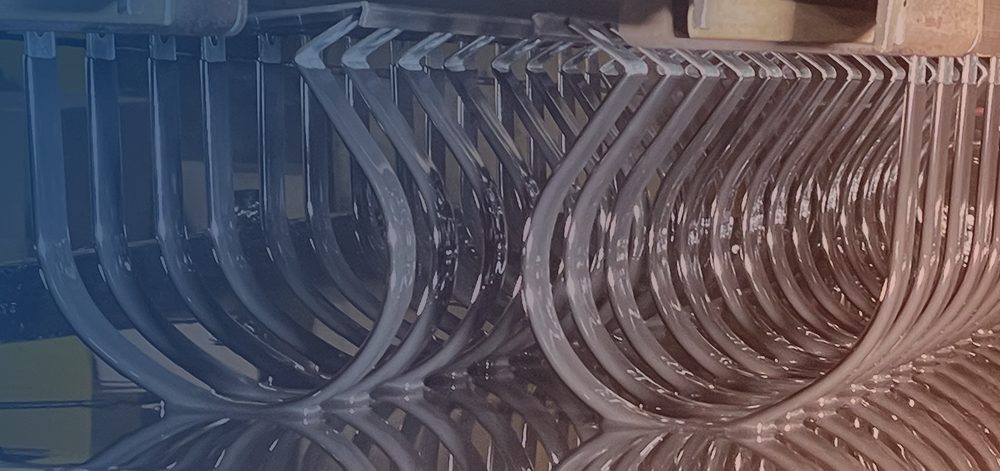

Finishing & Coating

EQUIPMENT:

- Rotary Tumbler

- Finishing Blaster

- Vibratory Deburr

- Custom Vinyl Coating

MATERIAL:

- Carbon Steel

- Stainless Steel

- Aluminum

- Copper

- Vinyl Plastisol

PROCESSES:

- Tumbling

- Shot Blasting

- Deburring

- Vinyl Coating

- Anodizing

- Plating

- Heat Treating

- Painting (E-Coat, Powder Coat, Wet)

- Machining

Our Case Studies

Collaborative Engineering. Proven Results.

Every success story starts with collaboration. See how KMC helps OEMs solve design challenges and turn complex ideas into precision-engineered results.

What Our Customers Have to Say…

“When other suppliers fell off or stopped responding, KMC stayed engaged. Their determination and communication made all the difference — they kept the project moving when others gave up.”

“KMC didn’t just ship parts — they owned the outside processes and quality checks, coordinated vendors, and brought solutions to the table.”

“We rely on KMC for a high-volume part (~150,000 pieces/month). They ramped without stumbling and quality has been excellent.”

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

Get in Touch

It’s Easy to Get Started

Ready to collaborate? Schedule a meeting with our engineering team to explore how KMC can accelerate your next program.