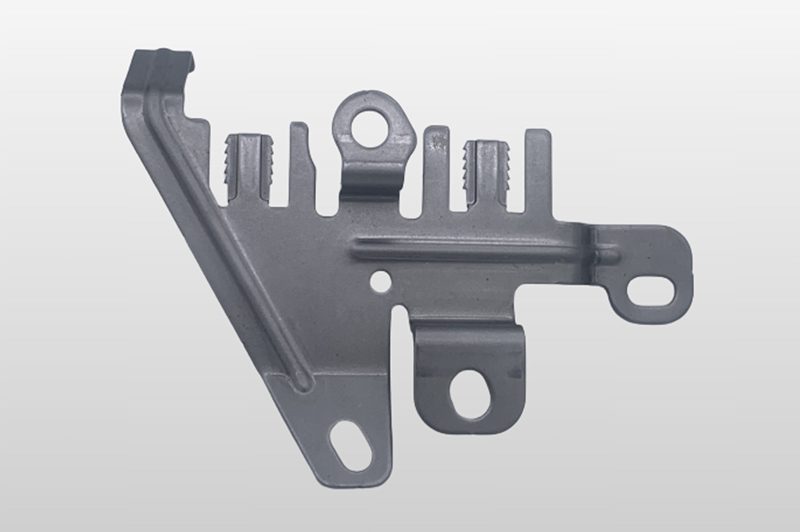

Tool Build & Die Engineering That Drives Performance

Integrated tool design, tool build, and engineering expertise that improves manufacturability, extends tool life, and ensures precision across every OEM production run.

KMC’s in-house tool & die team collaborates directly with OEM engineers to optimize designs, enhance dimensional precision, and deliver reliable, high-performance tooling for every program — from initial concept through full-scale production.

How We Do It Differently

By integrating tool design, fabrication, and maintenance under one roof, KMC helps OEMs achieve faster launches, tighter tolerances, and long-term cost efficiency.

In-House Tooling Expertise

Our dedicated tool and die shop designs, builds, and maintains tooling for consistent quality and reduced downtime.

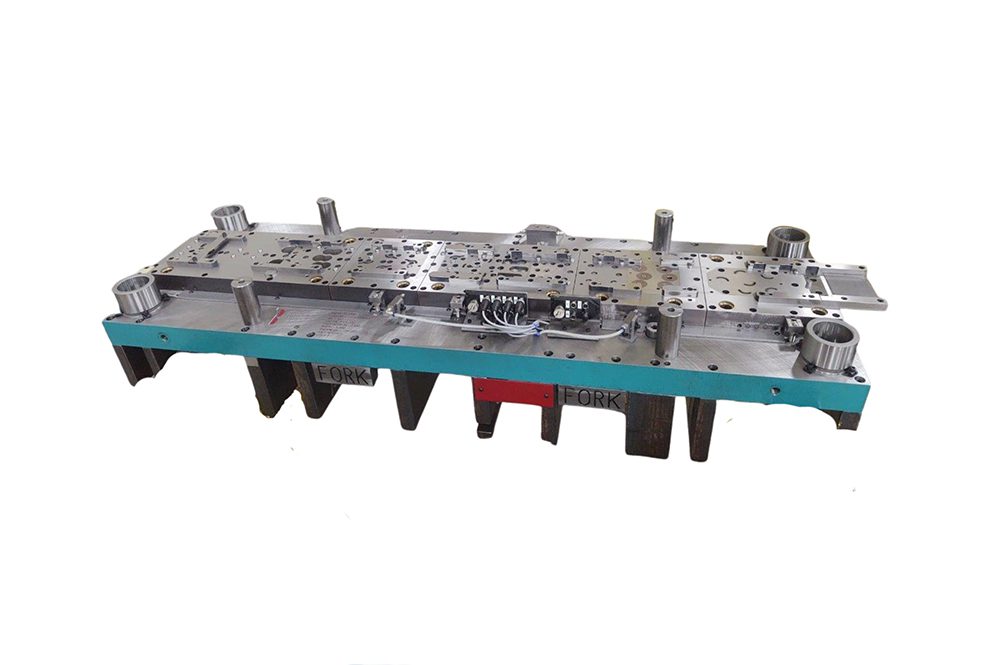

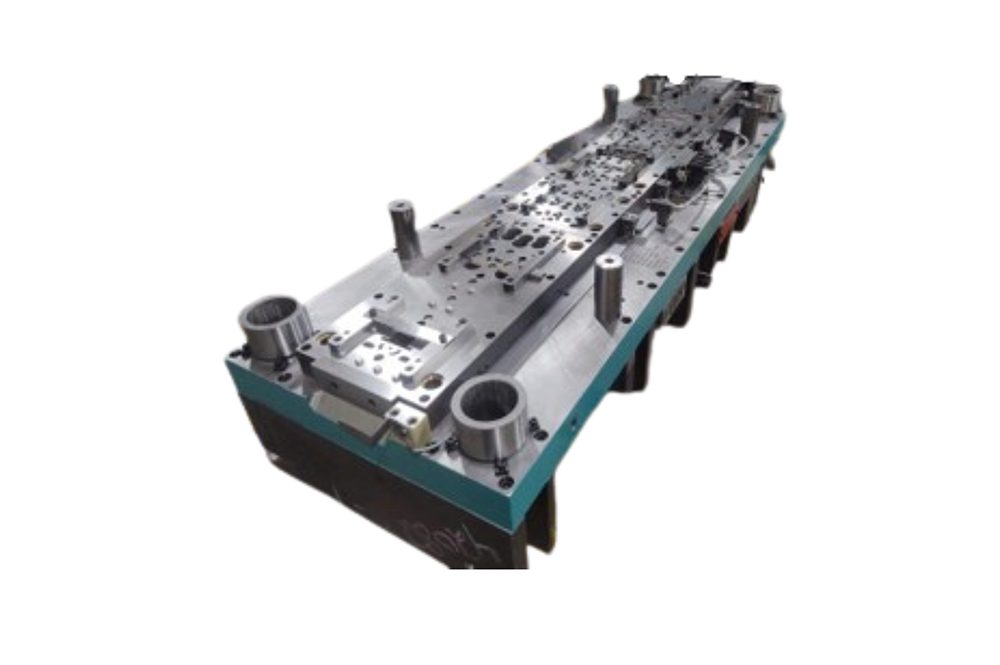

Precision Tool Build

We design and build precision tools in-house to ensure manufacturability, tight tolerances, and reliable performance across every production run.

Lifecycle Optimization

We manage the full lifecycle of your tooling—design, maintenance, and continuous improvement for sustained performance.

Let’s Build Something Better Together.

Tool Build & Die Engineering

Our Core Tool & Die Capabilities

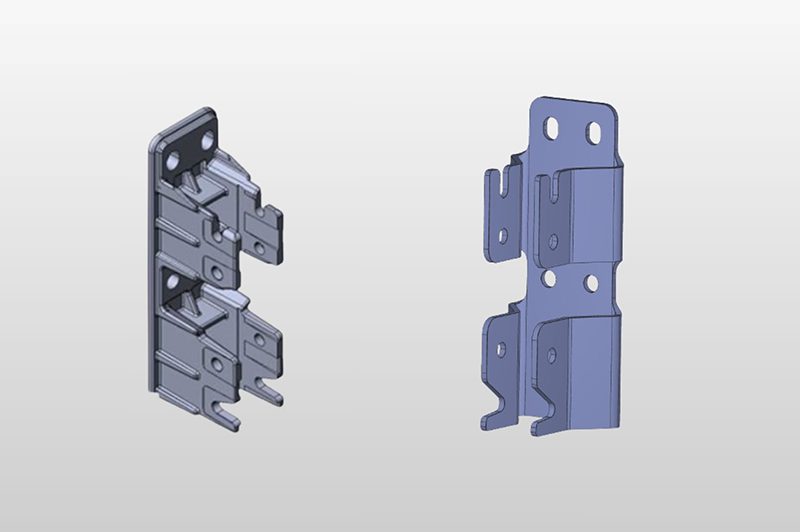

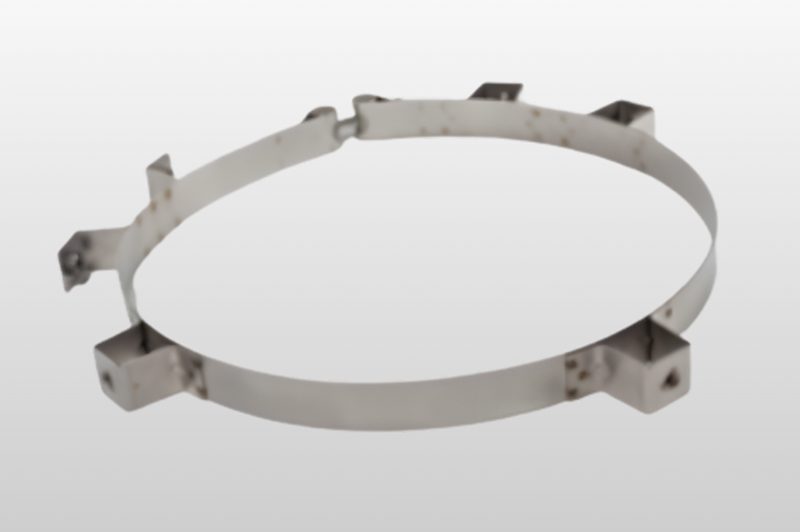

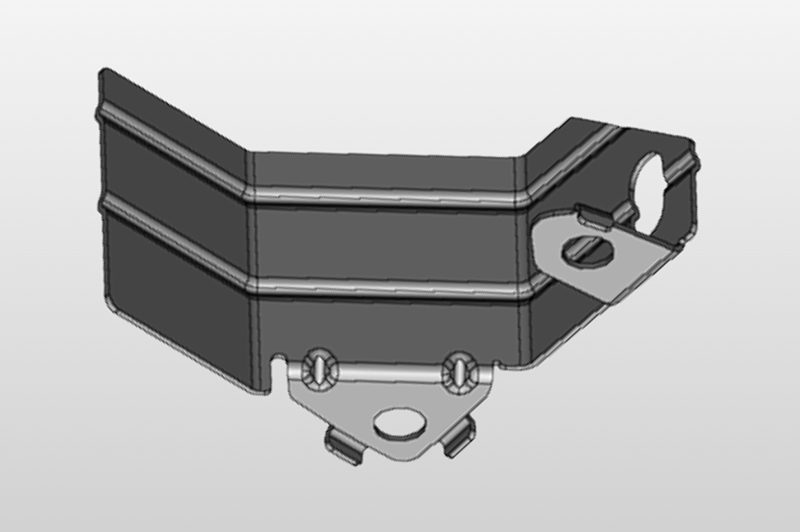

KMC’s tool and die engineering operations center on two core disciplines—Tool Design and Tool Build—delivering the precision, reliability, and innovation required for complex OEM components.

EQUIPMENT:

- SolidWorks, Logopress, PDM Tool Design Software

- Esprit CNC and WEDM offline programming

- Squaring, Machining & Grinding

- Heat Treat

- CNC, Hard Milling & Wire EDM

- Assembly and Development

- 200T Straight-side Press

- MarkForged FX10

MATERIAL:

- All Tool Steels – A2, D2, DC53, CPM

- Tool Steel Coatings

- Engineered Plastics

PROCESSES:

- New Tool Build

- PM, Repair and Improvement

- 3D Printing

- Re-source tooling

Our Case Studies

Collaborative Engineering. Proven Results.

Every success story starts with collaboration. See how KMC helps OEMs solve design challenges and turn complex ideas into precision-engineered results.

What Our Customers Have to Say…

“KMC is a very reliable supplier that lives up to their commitments on on-time delivery and quality. They make my job easier because I don’t have to chase updates or fix issues—they simply deliver.”

“KMC’s engineers don’t just tell us what can’t be done — they show us how it can be done. Every design challenge is met with a smart, practical solution.”

“When other suppliers fell off or stopped responding, KMC stayed engaged. Their determination and communication made all the difference — they kept the project moving when others gave up.”

“KMC didn’t just ship parts — they owned the outside processes and quality checks, coordinated vendors, and brought solutions to the table.”

“One of KMC’s biggest advantages is their in-house tooling division. They have full control over tooling design, cost, and lead time, which keeps projects on schedule and ensures parts are made right the first time.”

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

Get in Touch

It’s Easy to Get Started

Ready to collaborate? Schedule a meeting with our engineering team to explore how KMC can accelerate your next program.