Precision Metal Stamping for OEM Performance

Punch Press and Slide Forming solutions engineered for OEM performance and precision.

KMC delivers precision metal parts through advanced Punch Press and Slide Forming processes—engineered for manufacturability, consistency, and speed from prototype to production.

How We Do It Differently

KMC’s stamping process blends advanced tooling, in-house engineering, and collaboration. We partner with OEM engineers to design manufacturable, cost-efficient, and high-performing components from the first review to full production.

Engineering-Led Collaboration

Our engineers engage early in the design phase to identify risks, improve manufacturability, and reduce total part cost before production begins.

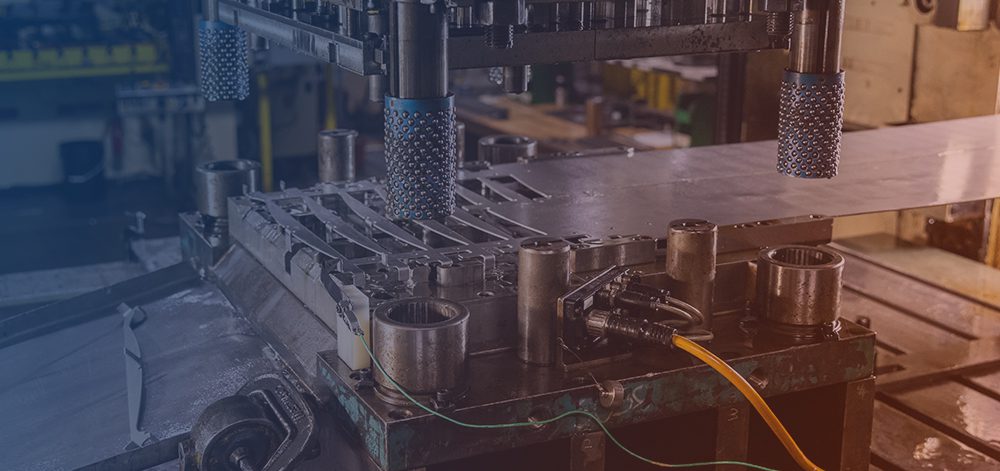

In-House Tool & Die

Complete tool design, build, and maintenance capabilities ensure faster lead times, precise tolerances, and reliable long-run performance.

Continuous Quality Control

Layered audits and certified systems guarantee part accuracy, consistency, and continuous improvement across every production run.

Let’s Build Something Better Together.

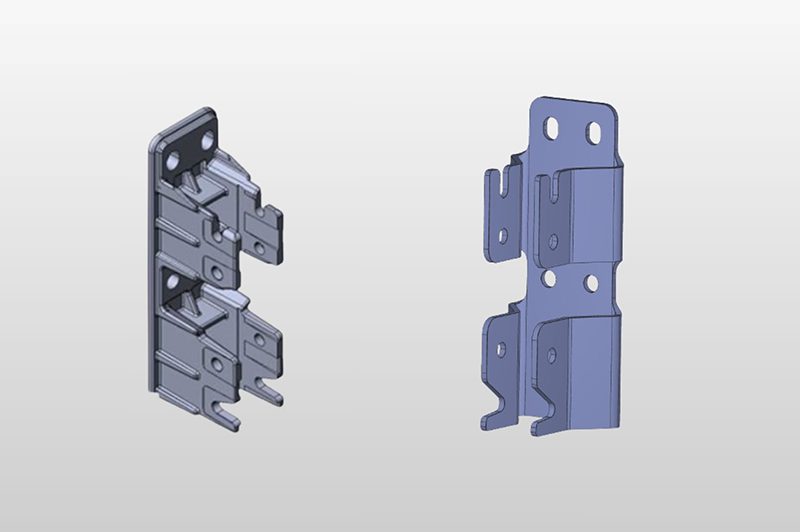

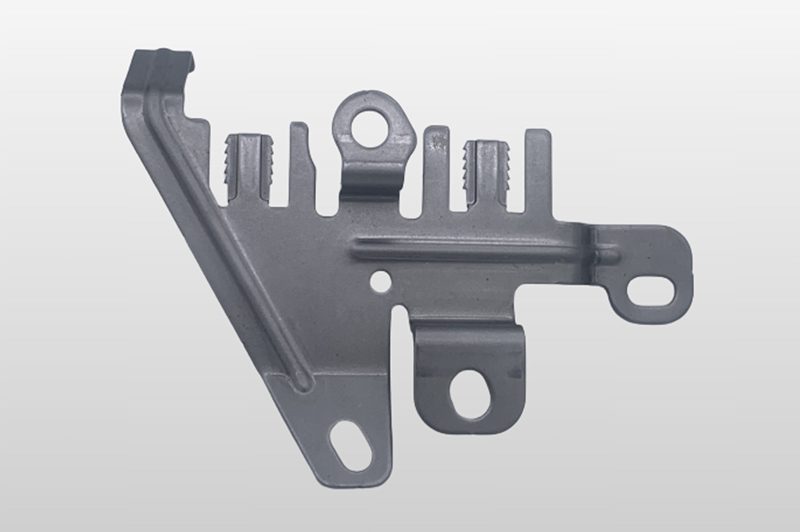

Precision Metal Stamping

Our Core Stamping Processes

KMC’s precision metal stamping operations center on two core processes—Punch Press and Slide Forming—delivering the flexibility, speed, and precision required for complex OEM components.

Punch Press

Our punch press lines deliver consistent, repeatable results for high-volume OEM components requiring strength, precision, and dimensional accuracy—ideal for structural and formed parts.

CAPABILITIES INCLUDE:

- Medium to long runs (50,000–1.5M EAU)

- Width up to 42 in (1,066.8 mm)

- Thickness up to 0.280 in (7.112 mm)

- 100–600 ton press range (Komatsu, Minster, Amada, Clearing, Seyi, Brown-Boggs)

- Progressive and transfer die operations

- In-house tool & die design, build, and maintenance

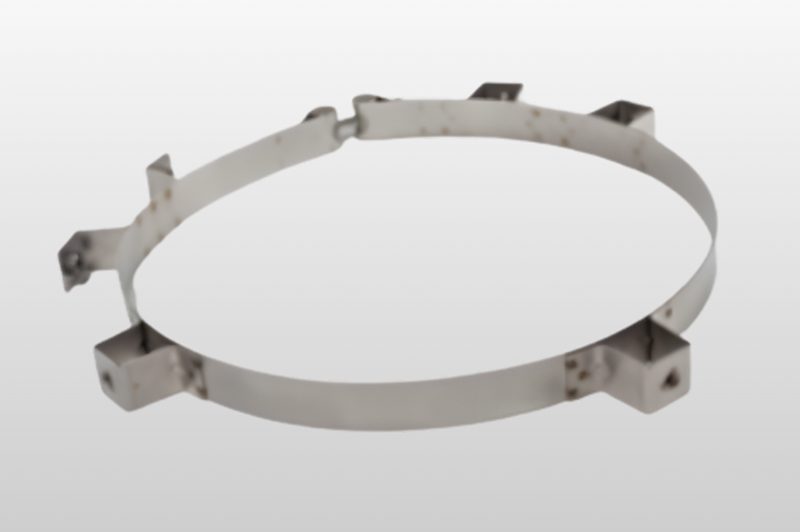

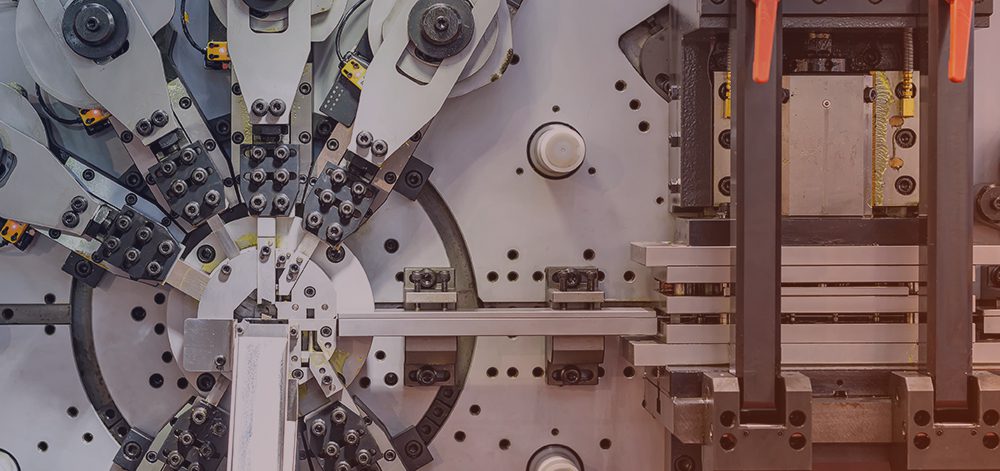

Slide Forming

KMC’s four-slide and multi-slide forming deliver unmatched flexibility for intricate, multi-bend geometries in steel, aluminum, copper, and brass.

CAPABILITIES INCLUDE:

- Feed length up to 15 in (381 mm)

- Width up to 3.75 in (95.25 mm)

- Thickness up to 0.120 in (3.05 mm)

- Standard and proprietary tool designs

- Integrated tapping, chamfering, dovetail forming

- Equipment: Nilson S2F, S3F, Baird 28/33/35/3-24, Nilson 1100

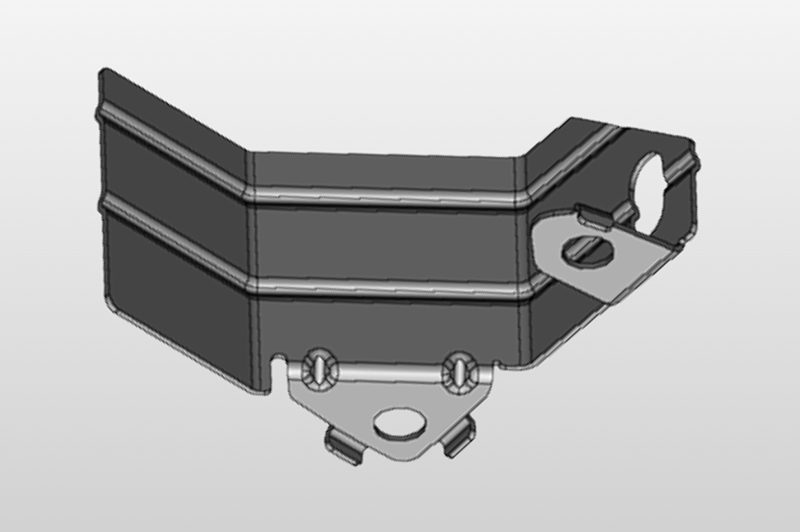

Our Case Studies

Collaborative Engineering. Proven Results.

Every success story starts with collaboration. See how KMC helps OEMs solve design challenges and turn complex ideas into precision-engineered results.

What Our Customers Have to Say…

“KMC’s engineers don’t just tell us what can’t be done — they show us how it can be done. Every design challenge is met with a smart, practical solution.”

“KMC does an excellent job collaborating with our engineering team to improve manufacturability. They don’t just make parts—they help us find smarter, more efficient ways to produce them.”

“Working with KMC requires very little hand-holding. I can share an idea, and they come back with an informed solution that’s usually right in line with where we were headed. They just get it.”

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

Get in Touch

It’s Easy to Get Started

Ready to collaborate? Schedule a meeting with our engineering team to explore how KMC can accelerate your next program.