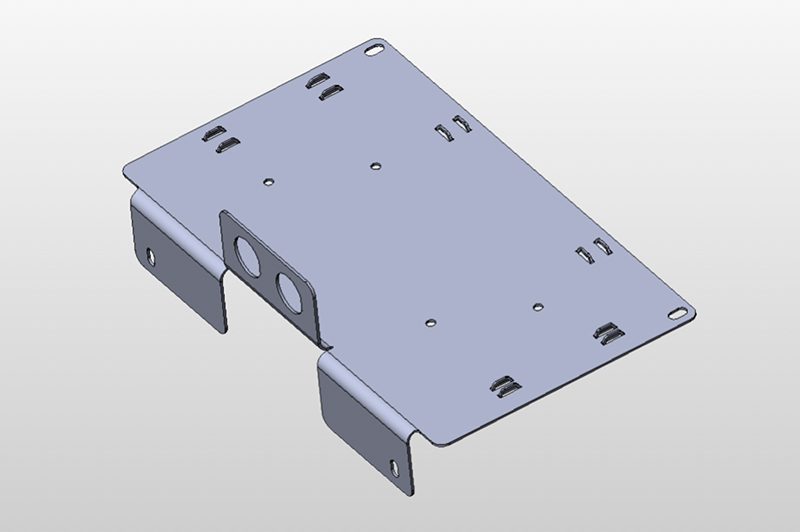

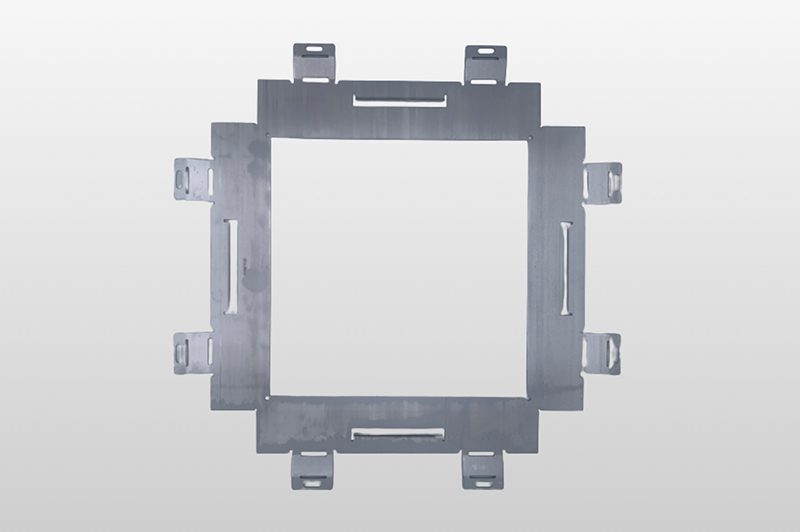

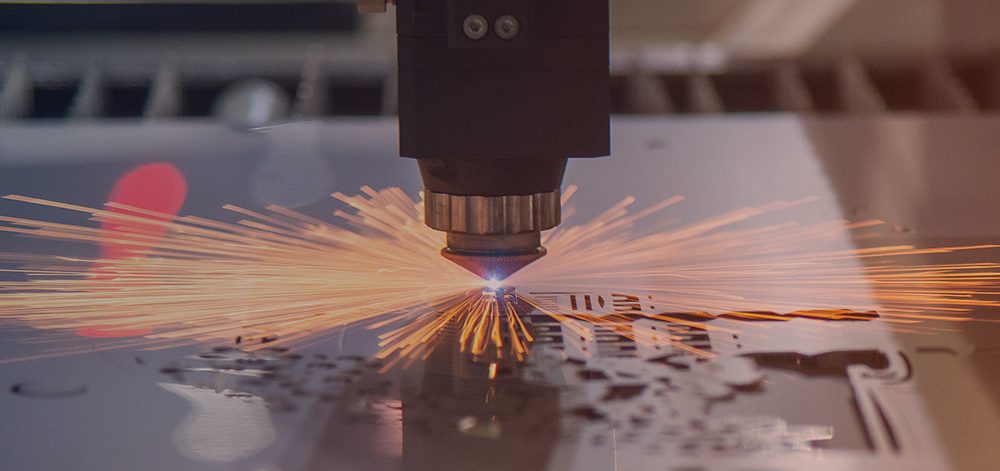

Precision Laser Cutting Built for OEMs

High-accuracy cutting and fabrication for complex metal components that demand consistency, speed, and collaboration from design through production.

KMC’s advanced laser cutting and fabrication services deliver precision, repeatability, and quality for OEM components—powered by engineering collaboration and decades of metal manufacturing expertise.

How We Do It Differently

From prototype to production, we pair modern laser technology with collaborative engineering to optimize material use, reduce rework, and ensure every cut meets your design intent.

Collaborative Engineering

Early design support improves manufacturability, minimizing waste and rework while enhancing component performance.

Advanced Laser Systems

State-of-the-art fiber lasers and press-brake equipment ensure precision, tight tolerances, and consistent part quality.

Flexible Production Scale

From low-volume prototypes to high-volume OEM programs, KMC adapts to your schedule and production needs.

Let’s Build Something Better Together.

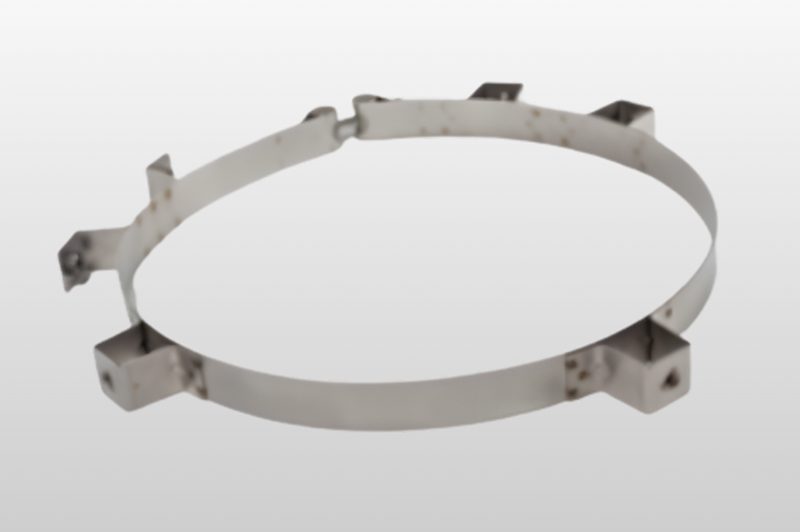

Laser Cutting & Fabrication

Our Core Fabrication Processes

KMC’s precision fabrication operations center on two core processes—Laser Cutting and Press Brake/Forming—delivering the flexibility, speed, and precision required for complex OEM components.

Laser Cutting

EQUIPMENT:

- Fiber, CO2 and Punch-Combination Lasers

- 3,000 – 12,000 watts and Automated Loading / Un-loading

MATERIAL:

- Up to 1” Carbon Steel

- Up to 1/2” Stainless Steel

- Up to 1/2” Aluminum

- Up to ¼” Copper

- Up to ¼” Brass

PROCESSES:

- Laser Cutting

- Punching, Lancing, Louvering

- Tapping

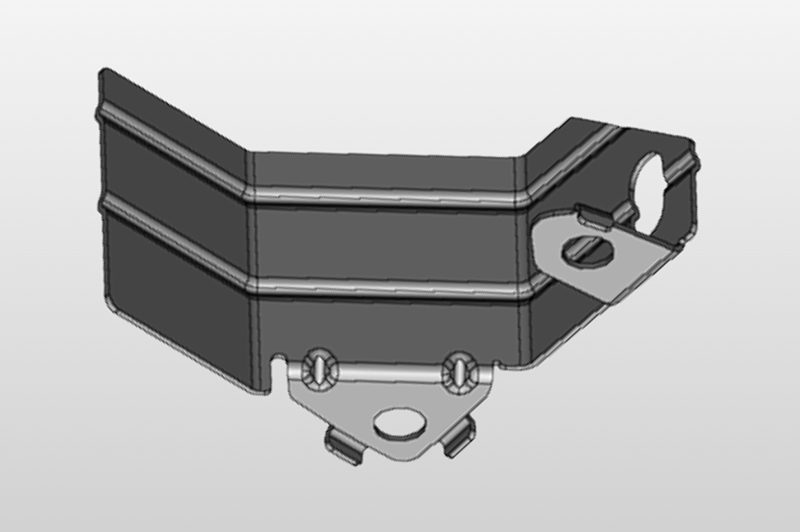

Press Brake / Forming

EQUIPMENT:

- Press Brakes

- Hydraulic Press

- Roll Forming

MATERIAL:

- All laser-cut materials

- Up to 8′ in length

PROCESSES:

- Robotic

- Manual

Our Case Studies

Collaborative Engineering. Proven Results.

Every success story starts with collaboration. See how KMC helps OEMs solve design challenges and turn complex ideas into precision-engineered results.

What Our Customers Have to Say…

“KMC is a very reliable supplier that lives up to their commitments on on-time delivery and quality. They make my job easier because I don’t have to chase updates or fix issues—they simply deliver.”

“KMC’s engineers don’t just tell us what can’t be done — they show us how it can be done. Every design challenge is met with a smart, practical solution.”

“When other suppliers fell off or stopped responding, KMC stayed engaged. Their determination and communication made all the difference — they kept the project moving when others gave up.”

“KMC didn’t just ship parts — they owned the outside processes and quality checks, coordinated vendors, and brought solutions to the table.”

“One of KMC’s biggest advantages is their in-house tooling division. They have full control over tooling design, cost, and lead time, which keeps projects on schedule and ensures parts are made right the first time.”

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

Get in Touch

It’s Easy to Get Started

Ready to collaborate? Schedule a meeting with our engineering team to explore how KMC can accelerate your next program.