Strategic Collaboration Drives Stamped Part Design Success

Introduction

A global leader in the design and manufacture of premium trucks was working to optimize part production and reduce costs within its Design Engineering and Assembly departments. When a critical component failed FEA testing in its initial casting form, project timelines were at risk. In need of a more flexible, cost-effective solution, the On-Highway Truck manufacturer collaborated with KMC to rethink the manufacturing approach and bring the design to life faster—without sacrificing strength or performance.

Challenges

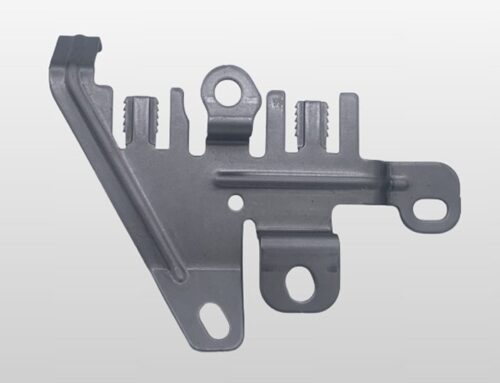

The original design for the part was based on aluminum casting, but the component failed FEA (Finite Element Analysis) testing, delaying program implementation. Casting tooling lead times and costs were also significant, and an interim design had to be PPAP’d (Production Part Approval Process) at a premium of $30 per part. A solution was needed that would reduce lead times, lower piece and tooling costs, and eliminate the need for temporary designs.

Solution

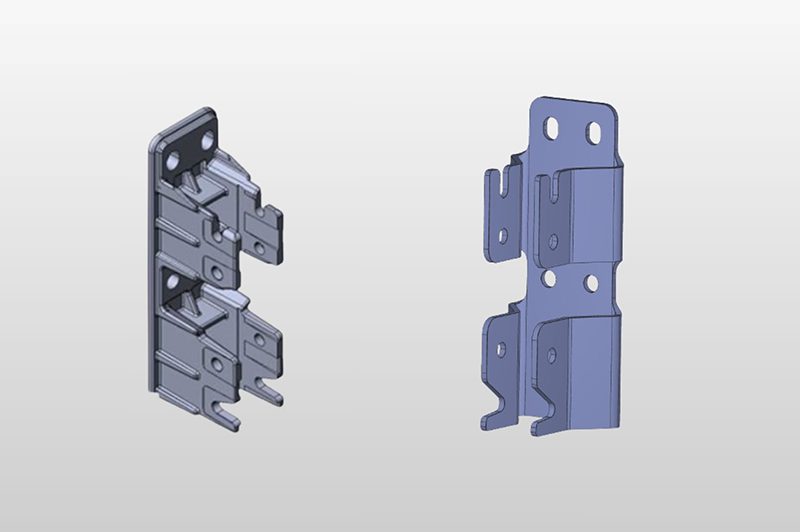

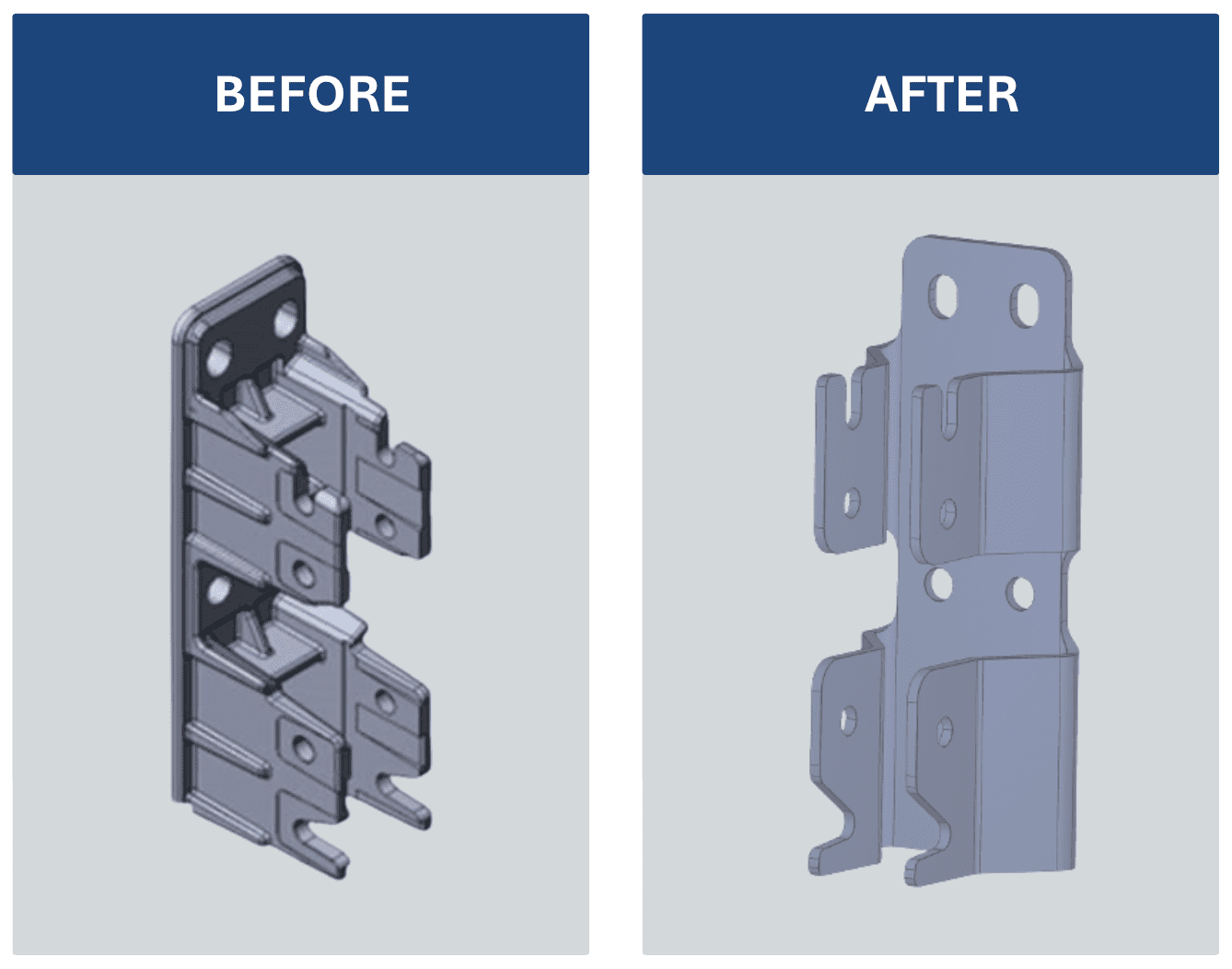

KMC collaborated with the manufacturer to develop a stamped alternative to the aluminum casting that met all structural requirements while streamlining production.

- Stamping drastically cut tooling lead times and reduced both part cost and tooling investment.

- KMC worked closely with the manufacturer’s design engineers, offering fresh insights into manufacturability.

- Through the support of prototype parts for early testing, KMC’s sales engineering team transitioned the part to a new manufacturing method.

Persistent collaboration between both companies’ engineers through design iterations were key to the project’s success.

Conclusion

By replacing the aluminum casting with a stamped part, the manufacturer avoided costly interim solutions and significantly shortened their implementation timeline. First-year savings totaled $1.3 million—including $840,000 saved by avoiding the initial design and an additional $300,000–$400,000 in tooling savings.

This project not only delivered measurable financial benefits but also strengthened the working relationship between KMC and the manufacturer’s engineering teams—proving that innovation and collaboration go hand-in-hand.