Why OEMs Are Returning to U.S. Manufacturing Partners Like KMC

KMC has been manufacturing in Wisconsin since 1908, serving OEMs in agriculture, heavy equipment, transportation, and industrial markets. As supply chains continue to shift, OEMs are rediscovering the advantages of partnering with domestic, engineering-led manufacturers like KMC .

The Case for Domestic Manufacturing

Offshore sourcing once promised lower costs—but frequent supply disruptions, communication gaps, and long lead times have led many OEMs to reconsider. By contrast, KMC’s U.S.-based facilities provide greater reliability, direct communication, and shorter production cycles .

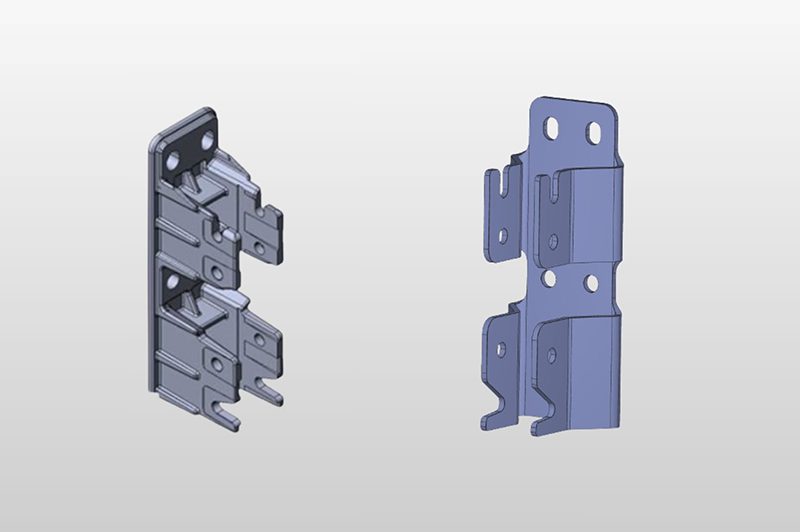

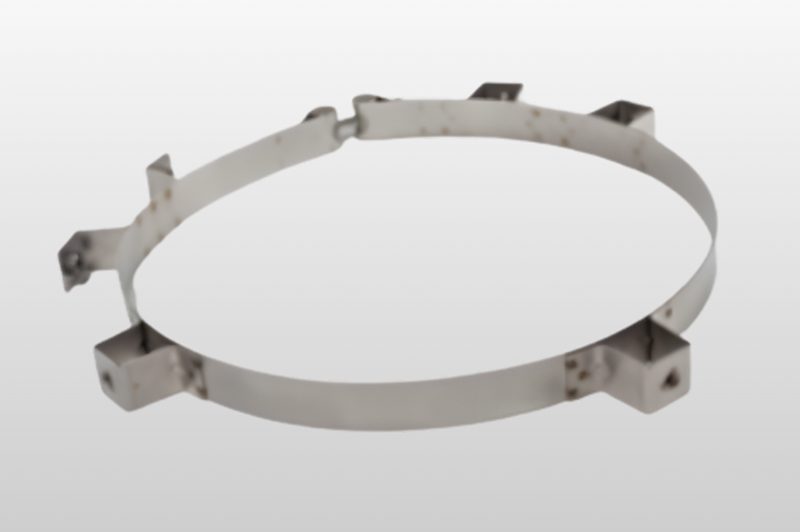

Integrated Capabilities Built for OEMs

KMC offers precision metal stamping, laser cutting, welding, and assembly—all under one roof. With flexible 250+ ton press lines, on-site tool and die engineering, and robust quality systems, KMC supports complex OEM programs from prototype through full production .

Certified Quality and Compliance

Every part KMC manufactures meets strict industry standards. The company maintains ISO and IATF-certified systems to ensure consistent, traceable quality across its processes—a requirement for top-tier OEM customers .

Engineering Access and Responsiveness

Local collaboration means faster feedback and better outcomes. KMC’s engineers communicate directly with OEM design teams, often identifying manufacturability improvements before production begins. This hands-on support is central to KMC’s long-standing OEM relationships .

A Legacy of Reliability

KMC’s century-long history and private ownership structure allow it to reinvest in technology and partnerships that strengthen its U.S. manufacturing base. With multiple Wisconsin facilities and a workforce of roughly 300, KMC is built to serve OEM programs with precision and stability .

Conclusion: The Strategic Value of Staying Close to Production

By reshoring programs to a domestic partner like KMC, OEMs gain more than cost control—they gain transparency, agility, and access to collaborative engineering expertise that directly impacts product success.

Let’s Build Something Better Together.

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

What Our Customers Have to Say…

“KMC is a very reliable supplier that lives up to their commitments on on-time delivery and quality. They make my job easier because I don’t have to chase updates or fix issues—they simply deliver.”

“KMC’s engineers don’t just tell us what can’t be done — they show us how it can be done. Every design challenge is met with a smart, practical solution.”

“When other suppliers fell off or stopped responding, KMC stayed engaged. Their determination and communication made all the difference — they kept the project moving when others gave up.”

“KMC didn’t just ship parts — they owned the outside processes and quality checks, coordinated vendors, and brought solutions to the table.”

“One of KMC’s biggest advantages is their in-house tooling division. They have full control over tooling design, cost, and lead time, which keeps projects on schedule and ensures parts are made right the first time.”