Collaboration in Action: Redefining Bracket Manufacturing

Introduction

A global automotive manufacturer and leader in cable and wiring systems, sought to reduce the cost and complexity of a multi-component bracket used in their electrical wiring assemblies. Their goal was to maintain strength while streamlining manufacturing for high-volume production.

Challenges

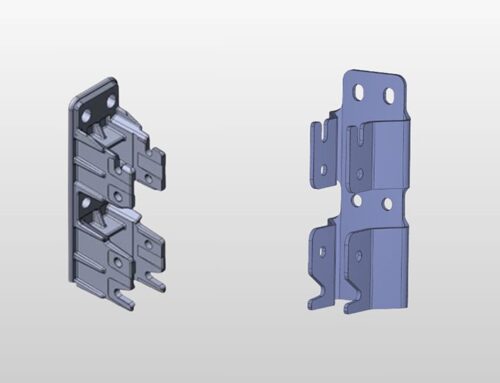

The manufacturer faced significant costs driven by the complex design and manufacturing of multiple metal brackets. The design required a strong bracket made from thicker material to ensure durability, but also included a delicate feature to hold an industry-standard electrical wiring component—forcing a balance between robustness and precision. The multi-part assembly, involving various processes like spot welding, further added to manufacturing costs and complexity.

Solution

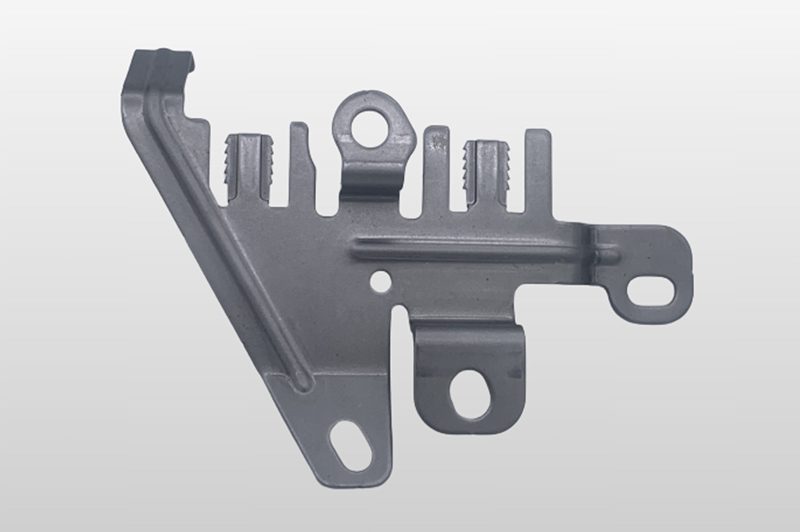

KMC collaborated with the manufacturer to create a single-piece bracket design using the thinnest possible material reinforced with strengthening ribs. A unique coining (stamping) feature was added around the connector area to precisely accept the electrical wiring component, eliminating the need for multiple brackets and assembly operations. Previously, the manufacturer used multiple metal brackets joined through processes like spot welding. Key advantages of KMC’s solution included:

- Simplified design with fewer components

- Lower part cost and weight

- Improved consistency and part quality

- High-speed production (1 part every 1.5 seconds)

- Robust bracket strength with precise fit for electrical components

Conclusion

The results of KMC’s solution were substantial:

- Delivered a more cost-effective, reliable part with improved production throughput—ideal for high-volume manufacturing.

- Achieved short lead times by completing the part in a single progressive stamping operation.

- Shipped 4.3 million parts since 2017, maintaining active production today. Annual savings estimated to be $420,000 to $700,000 over a minimum of 10 years.

KMC’s innovative approach has made them one of the manufacturer’s trusted partners, securing 5 out of 6 generations of transmission bracket business and earning exclusive supplier status for metal components through their expertise and customer-focused solutions.