A Strategic Collaboration to Cut Costs and Boost Reliability of a Heat Shield

Introduction

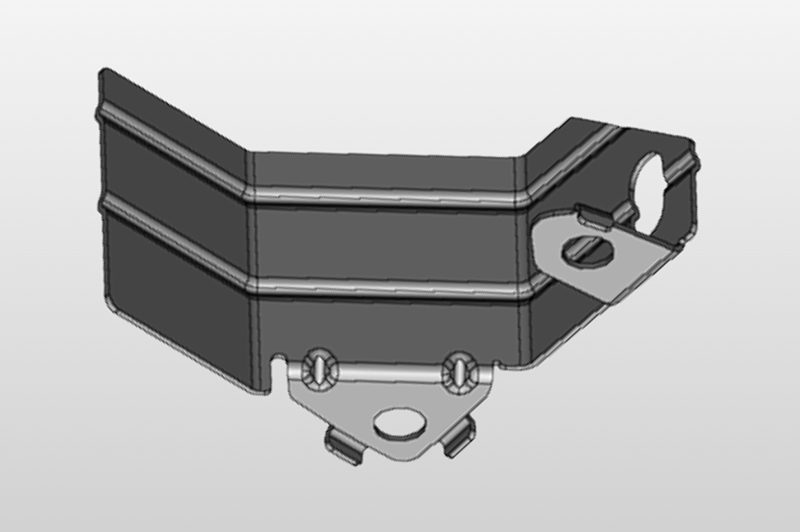

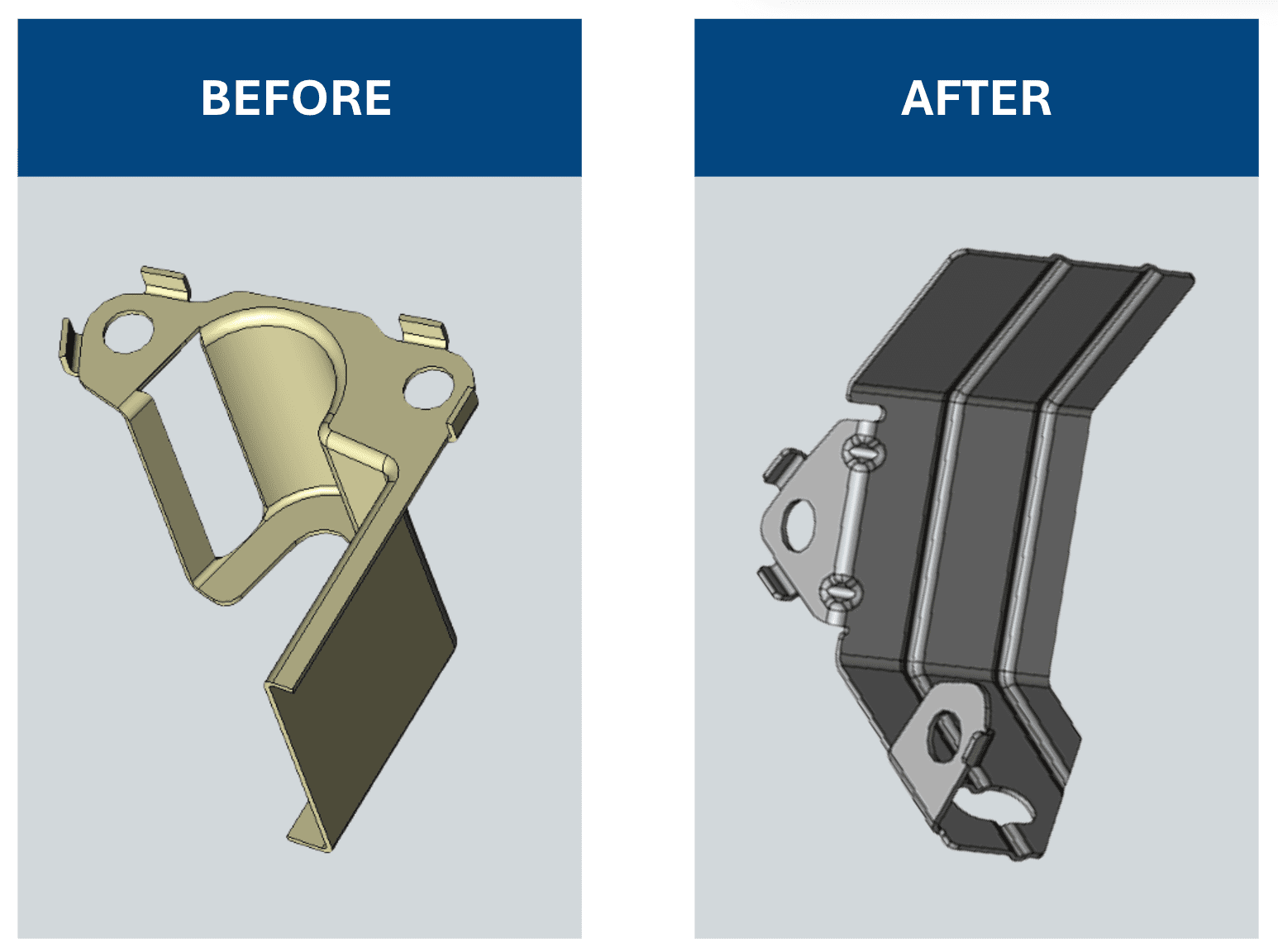

KMC collaborated with an automotive manufacturer to redesign a heat shield used in engine sensor applications. The original part was cost-prohibitive, difficult to manufacture, and lacked long-term corrosion resistance. A reengineering effort led to a simplified, more cost-effective solution with better overall performance.

Challenges

The existing aluminum design was prone to cracking, making it unfit for production, and unsuitable for high-temperature environments. The original heat shield design presented several challenges:

- Required expensive special tooling and draw-quality steel

- High material consumption and a costly secondary plating operation

- Poor long-term corrosion resistance after exposure to engine heat

- Overall part cost was too high, and sourcing at the target price was not feasible

Solution

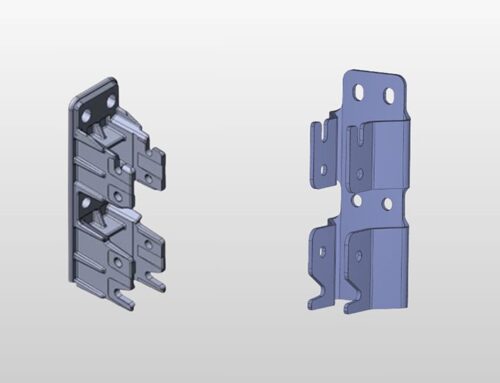

KMC proposed a complete redesign of the part, addressing both cost and manufacturability. The new design did not require any changes to adjacent parts or the existing assembly process, simplifying implementation and approval. KMC provided a manufacturable alternative that met performance and cost goals while accelerating the development timeline.

- Eliminated the cracking issues present in the drawn aluminum version

- Used simpler tooling and less material

- Removed the need for outside plating operations

- Delivered a cost-effective solution that also improved thermal and corrosion resistance

Conclusion

By streamlining operations and enhancing performance, KMC delivered a superior, cost-effective solution that gave the manufacturer a clear competitive advantage:

- Reduced tooling cost by $21,000

- Dropped part cost from $0.92 to $0.44 (based on 25,000 units annually), saving $12,000/year

- Accelerated development timelines, cutting:

- Off-tool sample lead time by 5 weeks

- PPAP (Production Part Approval Process) lead time by 7 weeks