Gusset Feature vs Weld: A Metal Component Collaboration Success

Introduction

A global leader in the design and manufacture of premium trucks, collaborated with KMC to optimize a newly designed component through innovative manufacturing strategies.

Challenges

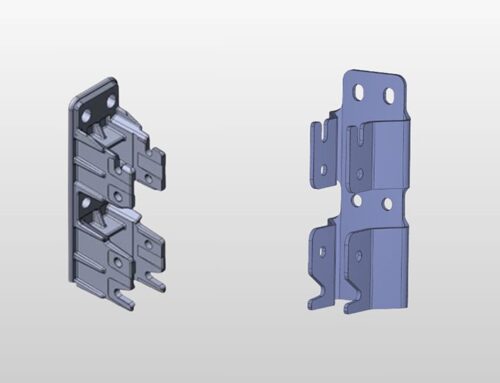

The manufacturer needed to optimize a newly developed part by eliminating unnecessary complexity while maintaining performance. The main goals were to:

- Eliminate welded components

- Reduce part and tooling costs

- Decrease manufacturing lead times

Although the part was new and had no legacy issues, the manufacturer required a forward-thinking partner to help refine the design before full-scale release.

Solution

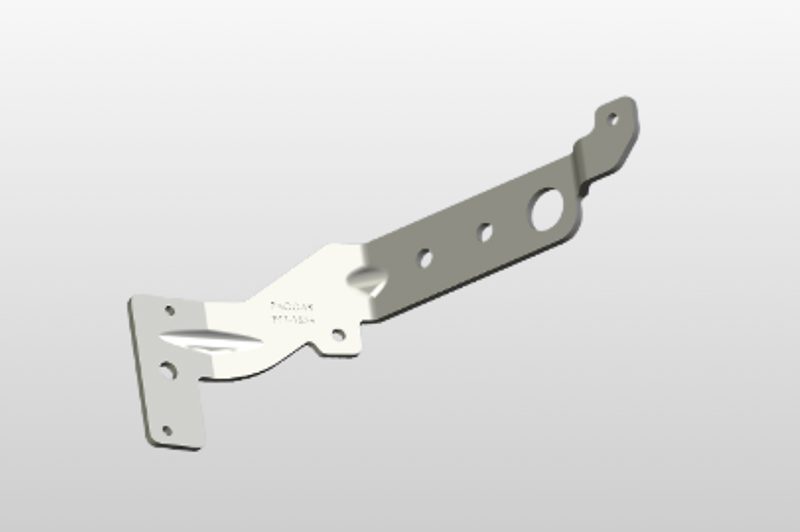

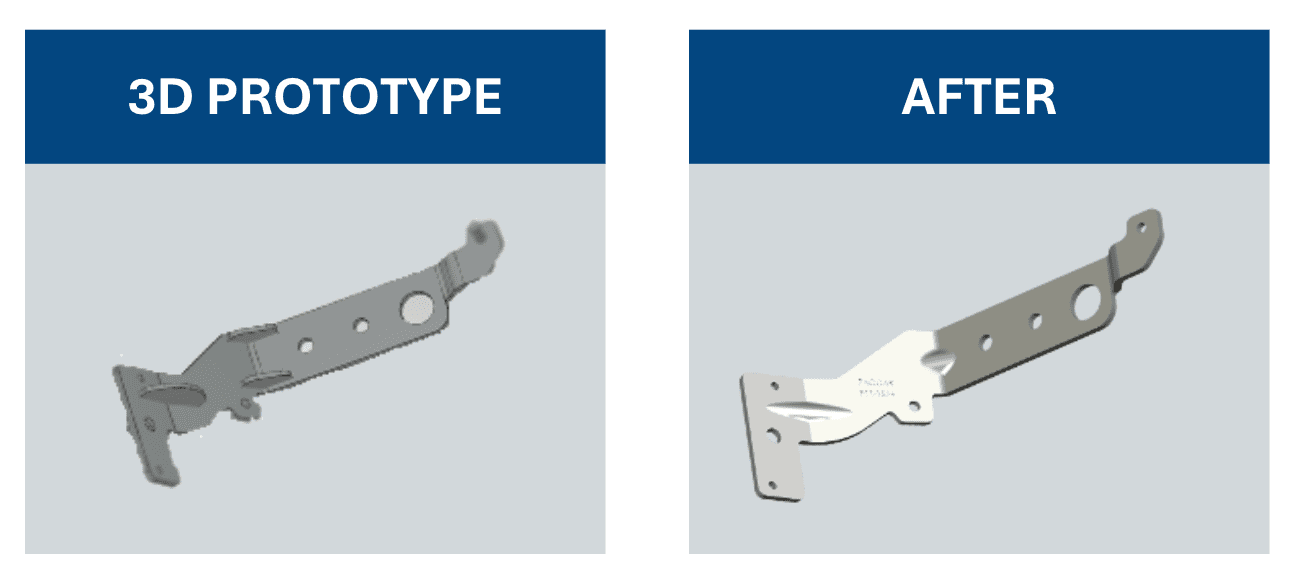

KMC proposed a collaborative approach early in the design stage by supplying prototypes based on their suggested optimizations. The core improvements included:

- Removing welded gussets

- Incorporating formed strengthening features using standard tooling

This strategy eliminated unnecessary components and processes, significantly reducing overall part complexity. KMC stood out as the only supplier in the quoting process who offered design collaboration aimed specifically at cost savings while maintaining functionality.

Conclusion

KMC’s solution delivered measurable value across multiple dimensions:

- Annual cost savings: $33,000

- Tooling savings: $7,800

- Reduced lead times through the elimination of welding processes

- Improved supplier engagement: the manufacturer’s engineers now proactively share new designs with KMC for review

KMC’s early collaboration and proactive design approach played a key role in helping the manufacturer achieve its goals.