Stamping Collaboration Cost Reduction

Introduction

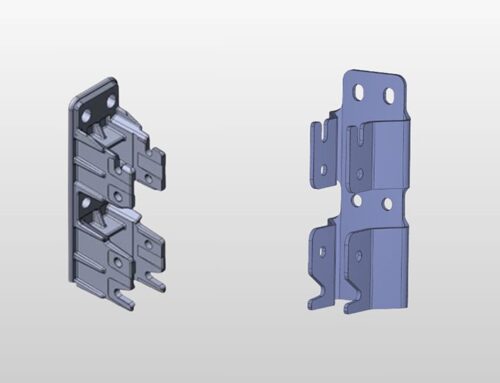

Based on the success of previous collaborations, engineers from a Heavy Equipment manufacturer approached KMC for a lower cost alternative to a traditionally high-cost casting. The goal was to eliminate excess costs through changes to the manufacturing process without compromising performance.

Challenges

The manufacturer sought to reduce the cost of a specific component previously made using cast powdered metal and extensive machining operations. Their existing process was expensive, with estimates ranging between $130–$150 per part. They needed:

- A lower-cost solution

- A partner with proven manufacturing innovation

- Confidence that performance would not be compromised

Solution

KMC proposed and implemented a stamping-focused redesign:

- Utilized a laser-cut blank to ensure precision and material efficiency

- Consolidated forming, center piercing, and perimeter trimming into a single die operation

- Subcontracted cleaning, rust protection, and 100% gauge-based inspection and sorting

- Several design iterations were made to ensure the stamped part met or exceeded performance expectations

Conclusion

The results delivered measurable impact:

- Approximate part savings of $882,000, improving the manufacturer’s bottom line

- Greater productivity through streamlined production

- Over 14,000 parts sold since 2018

- Tooling investment was offset by long-term savings

KMC brought forward an innovative manufacturing solution that directly addressed the manufacturer’s cost and performance goals solidifying KMC’s role as one of their trusted suppliers.