Proven Processes That Deliver Consistent Quality

Proven systems that uphold the highest manufacturing standards.

Our ISO 9001 and IATF 16949 certifications reflect more than compliance—they represent our culture of precision and accountability. Every KMC process, from design to delivery, is engineered for consistency and traceability. Because when quality is built into every step, excellence becomes the standard.

Our Process

Precision Engineered at Every Step

Collaboration & Feasibility

Design for Manufacturability validation ensures manufacturability before tooling starts.

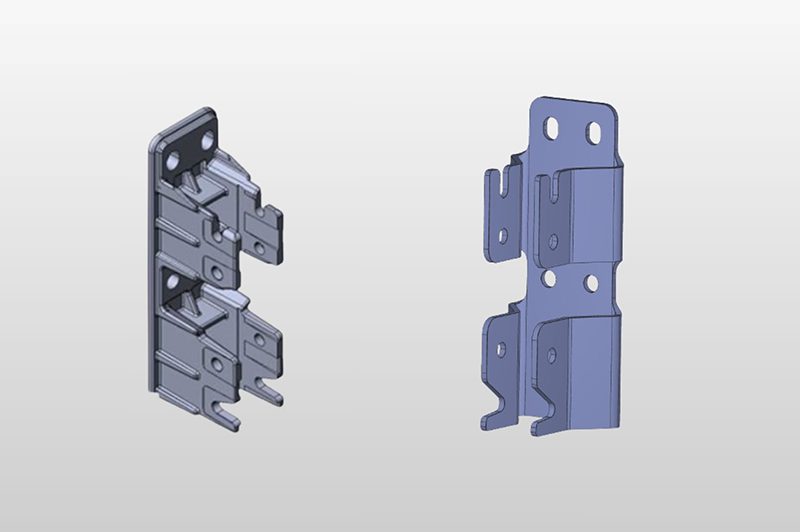

Tooling & Engineering

In-house die design and tool build.

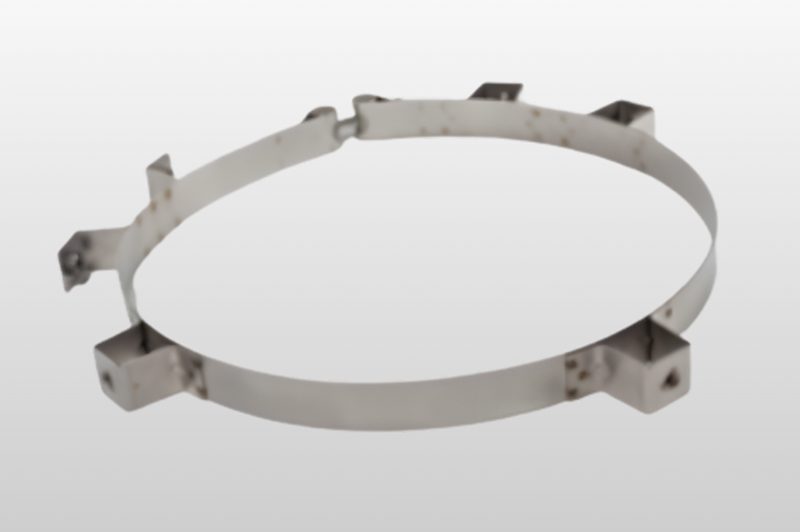

Stamping & Fabrication

100+ ton press lines, laser cutting and forming, robotic welding, and more — all under one roof.

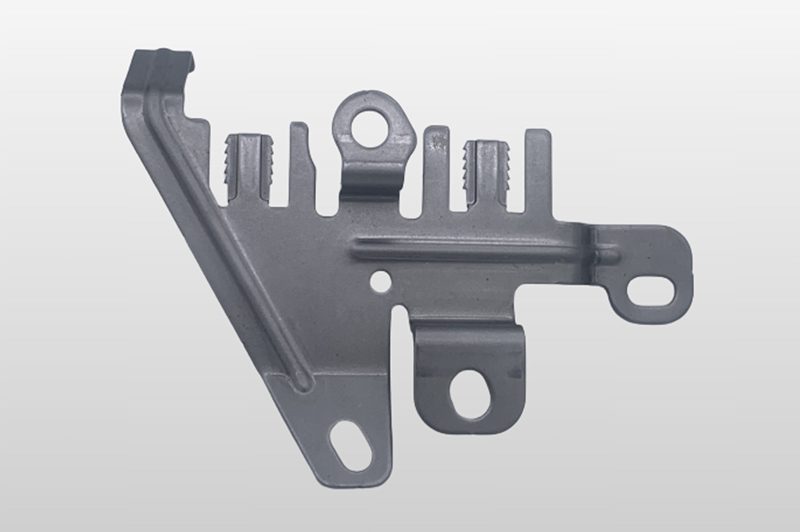

Assembly & Finishing

Complex subassemblies and part finishing with repeatable quality.

Inspection & Validation

Digital CMM verification, visual inspection, and PPAP documentation.

Continuous Improvement

Quality data fed back into design, manufacturing and quoting systems.

Our System

Where People, Process, & Technology Align

Our strength comes from how we work — combining skilled people, disciplined processes, and advanced technology into one connected system. Every quote, part, and project moves through a digital ecosystem that unites engineering, production, and quality at every step.

- People: Experienced engineers, technicians, and quality specialists dedicated to doing it right the first time.

- Process: Documented standards and lean workflows that ensure consistency and repeatability.

- Technology: Integrated systems like HubSpot and Paperless Parts connect data from design to delivery, driving traceability and continuous improvement.

By aligning people, process, and technology, KMC eliminates friction, improves accuracy, and delivers measurable results — every time.

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

What Our Customers Have to Say…

“When other suppliers fell off or stopped responding, KMC stayed engaged. Their determination and communication made all the difference — they kept the project moving when others gave up.”

“KMC didn’t just ship parts — they owned the outside processes and quality checks, coordinated vendors, and brought solutions to the table.”

“We rely on KMC for a high-volume part (~150,000 pieces/month). They ramped without stumbling and quality has been excellent.”

Our Case Studies

Collaborative Engineering. Proven Results.

Every success story starts with collaboration. See how KMC helps OEMs solve design challenges and turn complex ideas into precision-engineered results.

Get in Touch

It’s Easy to Get Started

Ready to collaborate? Schedule a meeting with our engineering team to explore how KMC can accelerate your next program.