Advanced Facilities & Technology Built for Precision

Modern facilities engineered for smarter manufacturing.

Our 250,000-square-foot operations combine decades of metalworking expertise with modern automation. From multi-station stamping and precision forming to advanced fabrication and assembly, every process is designed to deliver quality, efficiency, and flexibility—so our partners can move faster with complete confidence.

Our Facilities

250,000+ Sq. Ft. of U.S. Manufacturing Excellence

Corporate Headquarters

What we do here:

Press & Slide Manufacturing, Complex Assembly, Quality Management, Company Leadership, Sales, Customer Service, Supply Chain, Engineering, Finance, and Logistics.

1221 South Park Street

P.O. Box 348

Port Washington, WI 53074-0348

Walker’s Point

What we do here:

High Volume Slide Manufacturing, Vinyl Coating, and Logistics.

Mineral Springs

What we do here:

Laser & Fabrication, Press Brake, Welding, Prototyping, and Logistics.

Fredonia

What we do here:

Tool Build & Die Engineering, and Gages & Fixtures

Our Equipment

Advanced Manufacturing Equipment

Punch Press

- (1) Minster – 60 ton

- (4) Minster – 100 ton

- (1) Komatsu – 110 ton

- (1) Komatsu – 150 ton

- (1) Komatsu – 200 ton

- (1) Minster – 200 ton

- (1) Aida Servo Press – 220 ton

- (1) Amada – 220 ton

- (1) Komatsu – 300 ton

- (2) Aida Servo Press – 330 ton

- (1) Seyi – 440 ton

- (1) Brown Boggs – 600 ton

- (1) PTC – 660 ton

Laser & Punch Sheet Cutting

- (1) Trumpf Fiber Laser / Punch Combo with Automation

- (1) Amada Fiber Laser / Punch Combo with Automation

- (1) Trumpf 12,000 watt Laser with Automation

- (1) Trumpf 4,000 watt Fiber Laser

- (1) Trumpf 4,000 watt CO2 Laser

Press Brakes & Forming

- (1) Trumpf – 170 ton

- (1) Safan Darley Servo – 110 ton

- (1) Lauffer Hydraulic Press – 100 ton

- (2) Trumpf – 90 ton

- (2) Cincinnati Hydraulic – 90 ton

- (1) Bystronic Robotic Bend Cell – 80 ton

- (2) Accupress Hydraulic – 60 ton

- (1) Trumpf Servo – 40 ton

- (6) Hand Benders

- (1) Arcus Power Roller

Quality

- (1) Hexagon Metrology Coordinate Measuring Machine (CMM)

- (1) Romer Arm portable (CMM)

- (1) Keyence VL-800 3D Scanner

- (1) Keyence IMX 1000 Large Stage Multi Scanner (Vision, Laser, Probe)

- (1) Virtek Vision Laser Inspection System

- (2) Keyence Image Dimension Measuring Systems

- Keyence AI Inspection Camera Systems (Various)

- Optical Comparators (Various)

- Tesa Electronic Height Gages (Various)

- Mitutoyo Surface testers (Various)

- Material Hardness testers (Various)

Multi-Slide Presses

- (4) Nilson S2F

- (7) Nilson S3F

- (2) Nilson S4F

- (3) Baird 28

- (3) Baird 33

- (2) Baird 35

- (1) Baird 00

- (3) Automatic Extrusion

Welding

- (4) Miller Robotic Weld Cells (GMAW)

- (13) Resistance & Spot Welders (50 to 200 kVA)

- (3) Weld Booths (GMAW)

- (1) 2000 watt Manual Laser Weld Cell

Other Value Add Equipment

- (5) Vinyl Automated Dip & Cure Lines

- (3) Vinyl Manual Dip & Cure Lines

- Stoelting Aqueous Degrease & Wash Systems

- Faster Insertion (PEM, Rivnut, HUK) (Various)

- Torqued Bolt Assembly

- Vibratory Tumble & Finishing Equipment (Various)

Tool Design, Build, and Maintain

- (4) Mitsubishi Wire EDM

- Markforged 3D Printing (Engineered Materials) (Various)

- CNC Machining (Various)

- CNC Turning (Various)

- Wet and Dry Grinding Machine (Various)

- Heat Treat – Conventional & Atmospheric Ovens

Customer Sites Shipped To Each Year

Parts & Products Shipped Each Year

Sq. Ft. Across 4 U.S. Facilities

Years of Manufacturing Excellence

Trusted by Leading OEMs for Decades

What Our Customers Have to Say…

“KMC is a very reliable supplier that lives up to their commitments on on-time delivery and quality. They make my job easier because I don’t have to chase updates or fix issues—they simply deliver.”

“Working with KMC is straightforward. They’re proactive, thorough, and dependable—exactly what we look for in a long-term partner.”

“KMC’s quality has always been in line with our standards and strategy. Even as global competition increases, they remain a strong and trusted partner for our North American operations.”

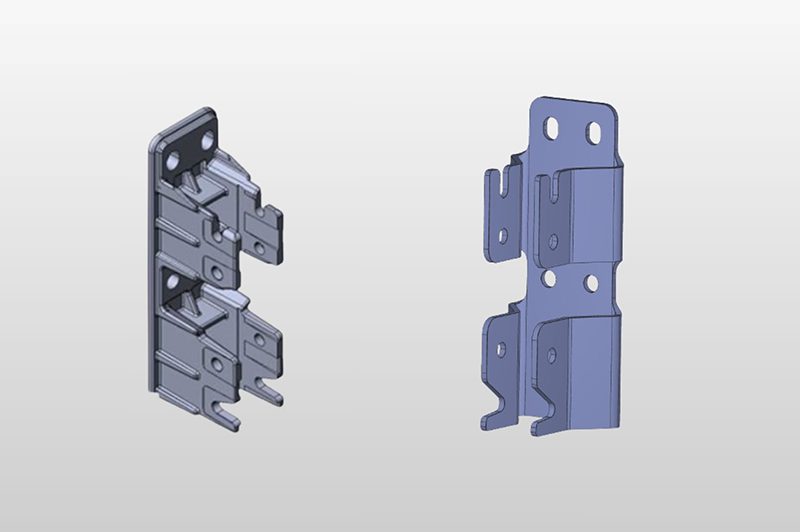

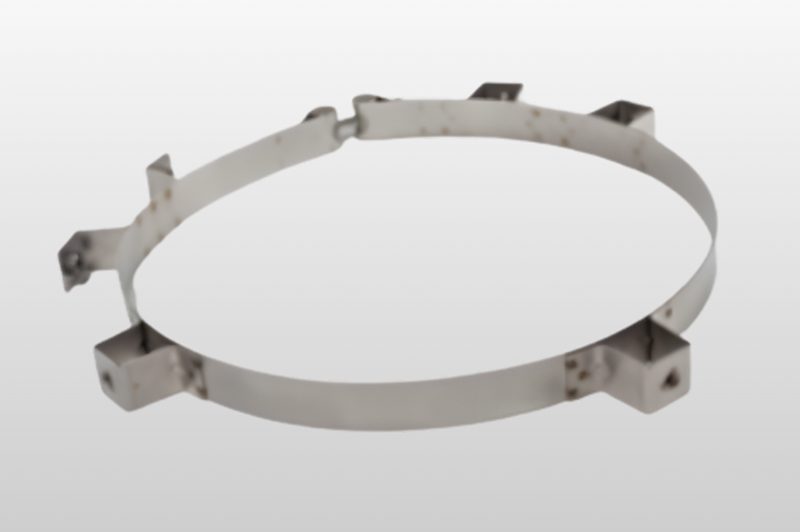

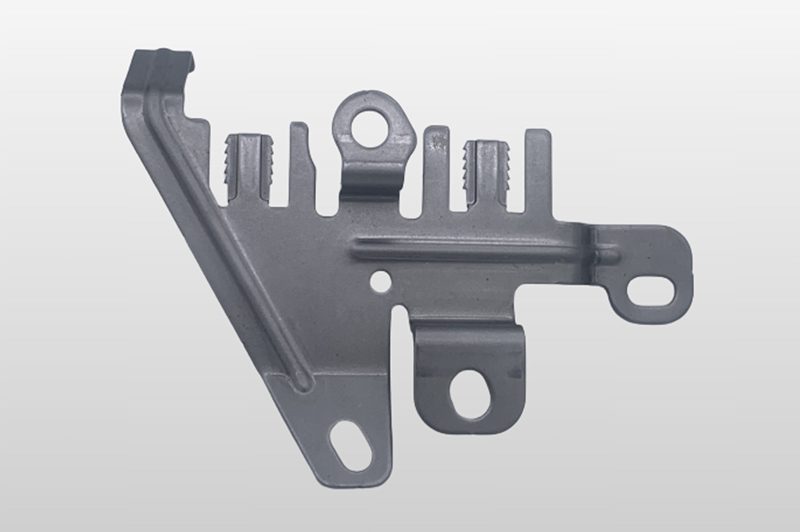

Our Case Studies

Collaborative Engineering. Proven Results.

Every success story starts with collaboration. See how KMC helps OEMs solve design challenges and turn complex ideas into precision-engineered results.

Get in Touch

It’s Easy to Get Started

Ready to collaborate? Schedule a meeting with our engineering team to explore how KMC can accelerate your next program.